CNC milling machining for complicated parts

1. CNC milling machine

One of the commonly used CNC machining methods can control the movement of multiple coordinate axes (3-5 axes) at the same time, and keep them in a predetermined movement relationship, so as to process the workpiece into a certain shape part.

The CNC milling machine can mill all kinds of parts surface, groove cavity, plane contour, three-dimensional contour and complex surface parts.

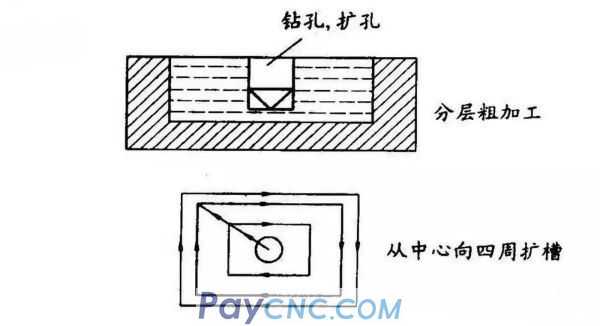

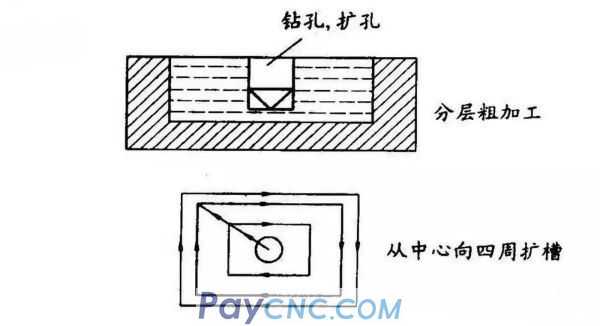

Process treatment: the processing route is determined, as shown in the figure

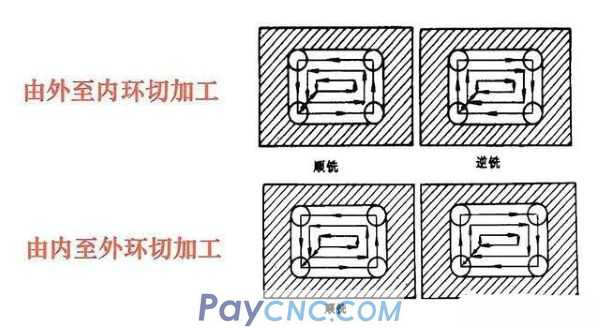

Milling route, as shown in the figure:

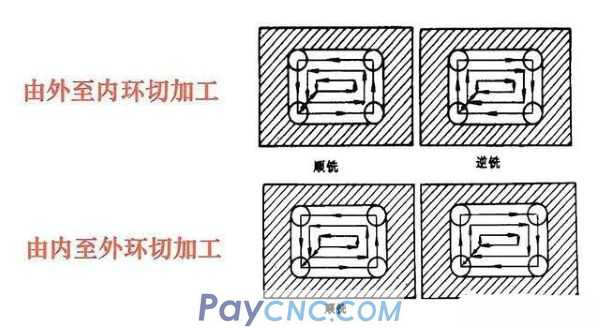

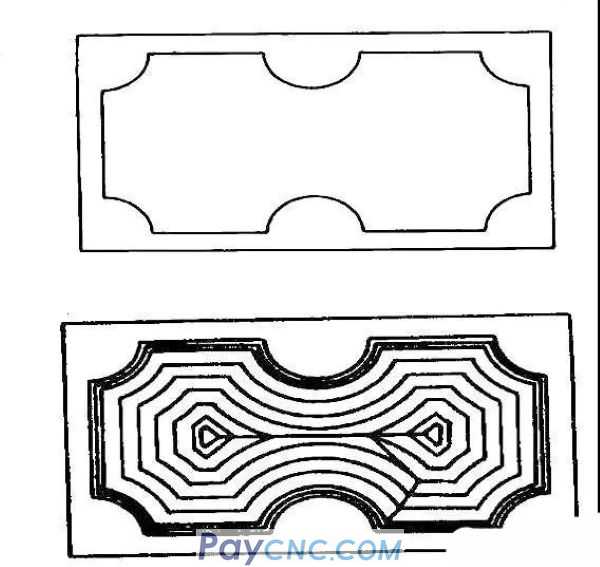

Complex cavity ring type plus, as shown in the figure:

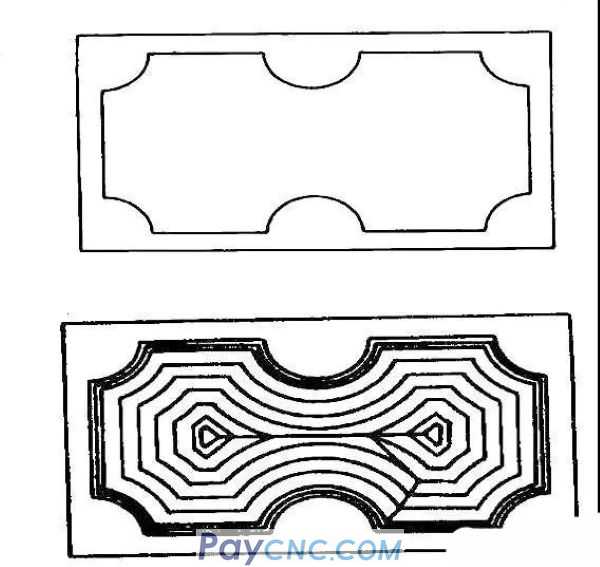

Cavity machining with islands, as shown in the figure:

"Line cutting method" processing surface as shown:

Three-coordinate and five-coordinate machining of the curved surface, as shown in the figure:

Programming features and commonly used commands: linear interpolation, arc interpolation, polar coordinate interpolation, parabolic interpolation, spiral interpolation, involute interpolation, spline interpolation, etc.

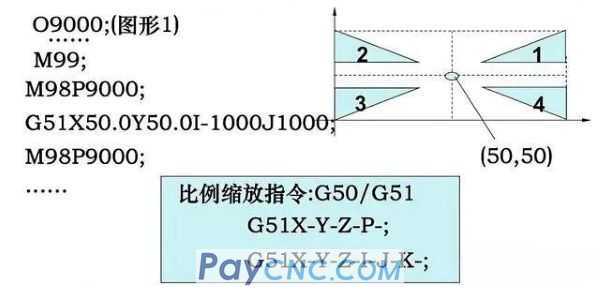

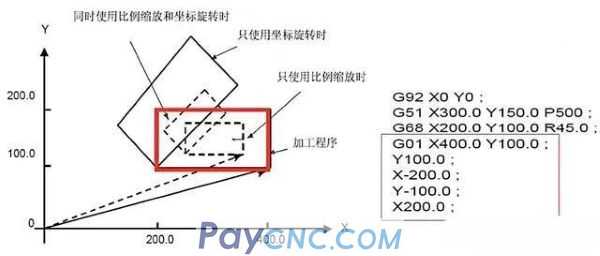

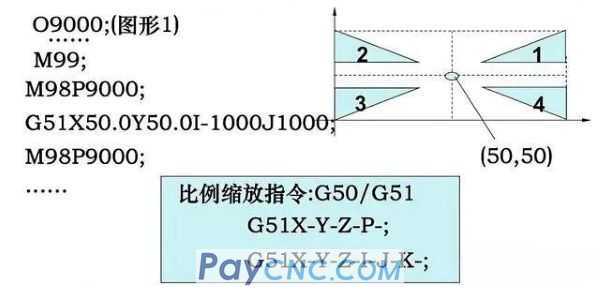

Use proportional zoom to realize the mirroring function, as shown in the figure:

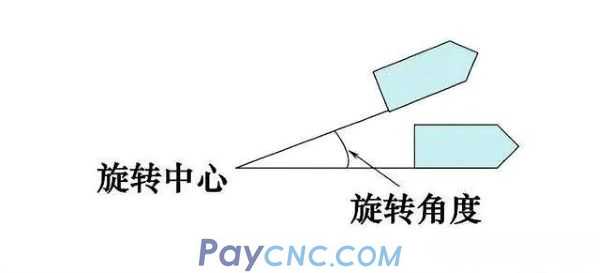

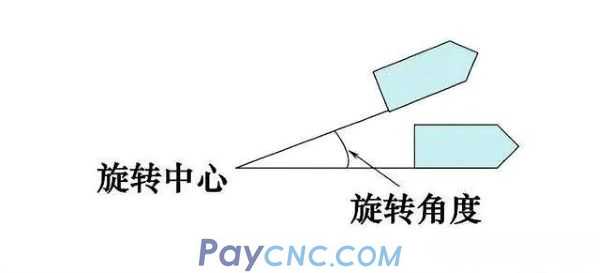

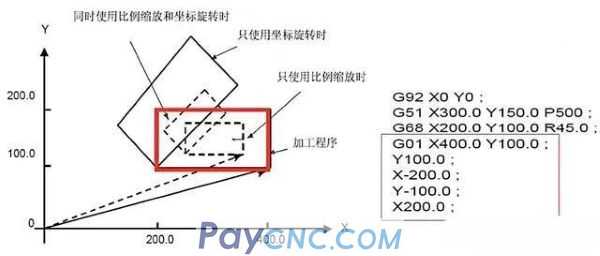

Coordinate commands: G68, G69, G17/G18/G19 G68, X-Y-Z-R-; rotation center (X, Y, Z), R rotation angle, reverse (positive) G69 cancel. as the picture shows:

G54~G29 commands, the coordinate points are shown in the figure:

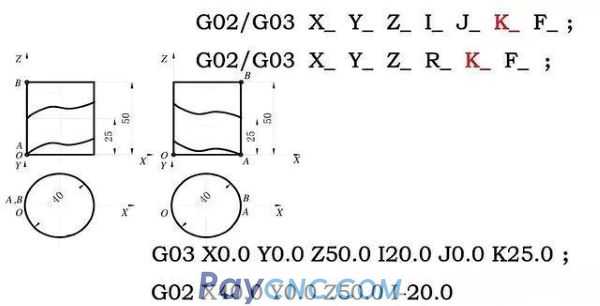

Instruction format, as shown in the figure:

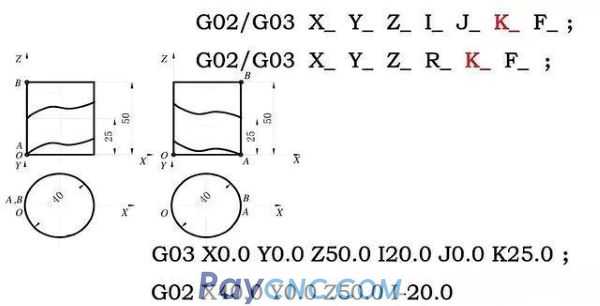

Spiral interpolation instruction, as shown in the figure:

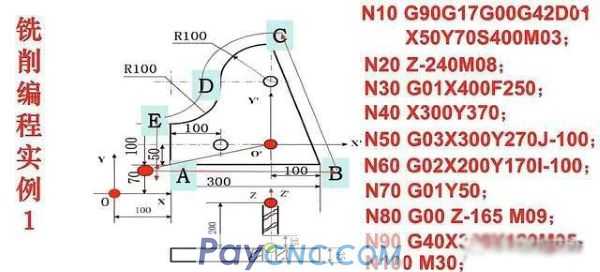

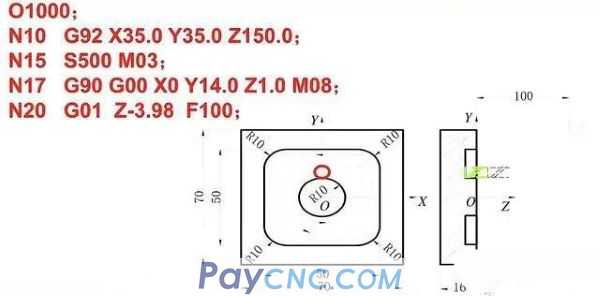

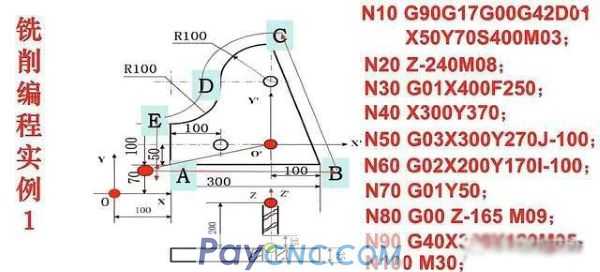

Example of milling programming, as shown in the figure:

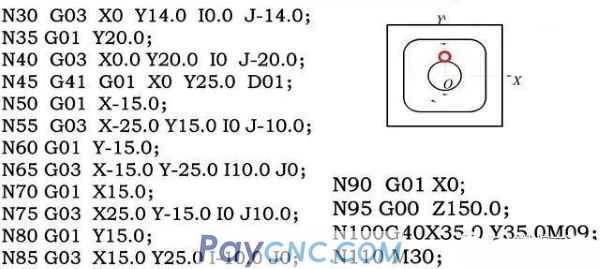

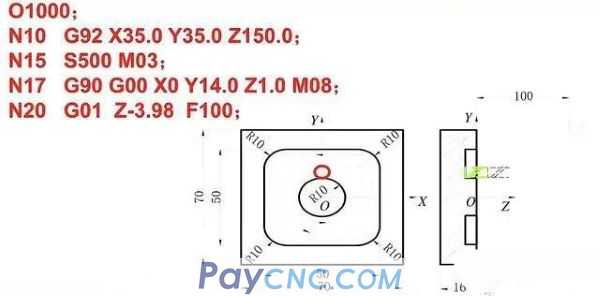

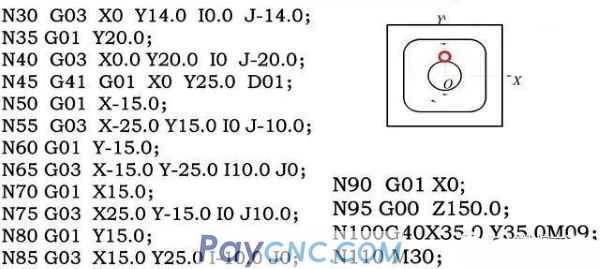

Sales programming example two, as shown in the figure:

One of the commonly used CNC machining methods can control the movement of multiple coordinate axes (3-5 axes) at the same time, and keep them in a predetermined movement relationship, so as to process the workpiece into a certain shape part.

The CNC milling machine can mill all kinds of parts surface, groove cavity, plane contour, three-dimensional contour and complex surface parts.

Process treatment: the processing route is determined, as shown in the figure

Milling route, as shown in the figure:

Complex cavity ring type plus, as shown in the figure:

Cavity machining with islands, as shown in the figure:

"Line cutting method" processing surface as shown:

Three-coordinate and five-coordinate machining of the curved surface, as shown in the figure:

Programming features and commonly used commands: linear interpolation, arc interpolation, polar coordinate interpolation, parabolic interpolation, spiral interpolation, involute interpolation, spline interpolation, etc.

Use proportional zoom to realize the mirroring function, as shown in the figure:

Coordinate commands: G68, G69, G17/G18/G19 G68, X-Y-Z-R-; rotation center (X, Y, Z), R rotation angle, reverse (positive) G69 cancel. as the picture shows:

G54~G29 commands, the coordinate points are shown in the figure:

Instruction format, as shown in the figure:

Spiral interpolation instruction, as shown in the figure:

Example of milling programming, as shown in the figure:

Sales programming example two, as shown in the figure:

USD

USD