GSK 980MDi CNC System Drilling Solution

GSK980MDi drilling and milling machine CNC is a product based on GSK-Link bus technology developed by Guangzhou NC. It is equipped with a GR series bus-type servo drive unit and a multi-turn 17-bit absolute encoder servo motor to achieve 5 axes and 5 linkages. High-speed and high-precision motion control with 0.1um and maximum running speed of 100m / min. Support on-line configuration of servo parameters, on-line monitoring of servo status, and zero return of non-block mechanical.

Specially developed online CAM function for drilling and milling machines. After saving CAD files in DXF format and importing the files into the system, the system can display this file and post-process it. It can automatically generate drilling and milling slots without programming Type of processing program. In the application process, colors can be used to distinguish according to different size graphics, and different tools are selected when maintaining and automatically generating files in the system.

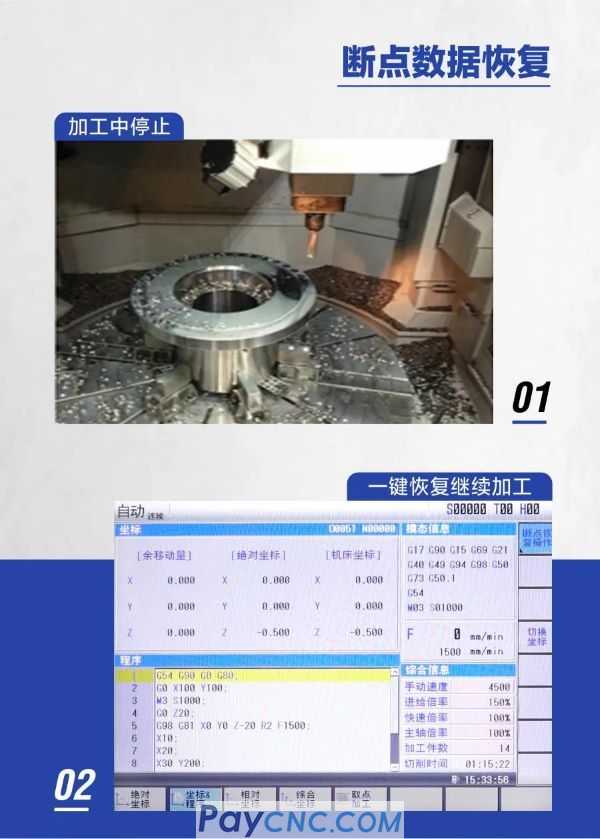

In the process of drilling, after the processing is interrupted due to an accident, simply press the "Breakpoint Data Recovery" button, and you can restore the previous processing position and state with one click to achieve continuous processing of the workpiece.

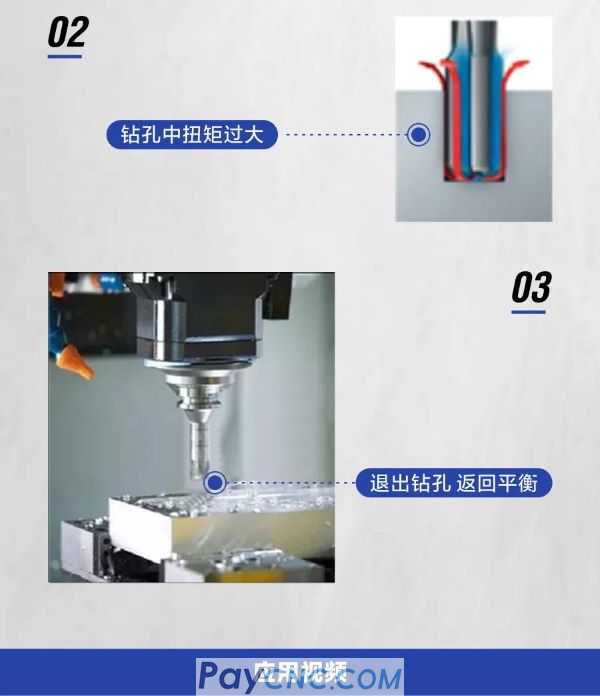

When drilling, the system detects that the torque is greater than the set value, which may cause the tool to break. The system will stop drilling and return to the initial plane, prompting the customer to perform tool inspection and manual processing.

USD

USD