GSK 986G & 986GS Grinding CNC Examples 03

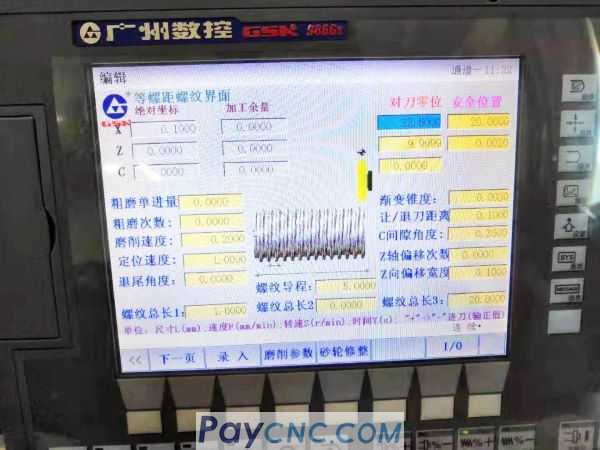

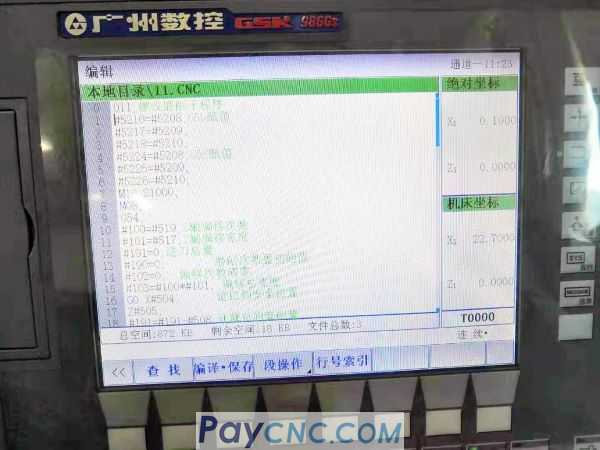

No.1Application of GSK986 CNC system thread grinding

Workpiece diameter 30-100mm, work piece length 100-1500mm;

The diamond grinding wheel is formed by one-time grinding without repeated clamping;

The inclination angle of the grinding wheel (thread spiral angle) is adjustable.

solution

Use the CNC indexing head to control the rotation angle of the grinding wheel, and add a hydraulic locking indexing head to solve the rigidity problem after stopping;

Use the absolute high-resolution motor as the workpiece rotation indexing, so that the indexing control is more stable, and the grinding finish is greatly improved;

Use the MPG intervention function to solve the problem of thread setting.

Application effect

Meet customer's workpiece processing needs;

Replacing the original imported vertical car processing, greatly saving the cost of equipment.

No. 2Application of GSK986 CNC System Cam Grinding

Workpieces with multiple cams, complete grinding with one clamping;

Automatically fit the track according to the lift table and follow the grinding;

With grinding repair, long repair, automatic repair wheel and automatic compensation function.

solution

Equipped with X / Z / C axis, C axis as indexing axis, follow-up grinding using G86 command;

The X axis is equipped with high resolution grating ruler to ensure the repeated positioning accuracy of the machine tool to ensure product consistency;

C axis is equipped with circular grating or high resolution servo motor;

Use the PC application independently developed by GSK986 to fit the trajectory of the lift table.

Application effect

One-time clamping completes the grinding of the entire camshaft, without the use of master grinding, and it is more flexible to switch workpieces;

The machining accuracy has been greatly improved, avoiding the situation where the precision of the master machine tool cannot be controlled due to the wear of the mold;

The addition of grating ruler has greatly improved the repeated positioning accuracy of the machine tool, and the product consistency control is better;

Intermediate repairs and longer repairs make the effect of wheel wear on workpiece accuracy less.

No. 3

Application of eccentric grinding in GSK986 CNC system

Workpiece diameter 12-50mm, eccentricity 0.5-3.5mm;

Workpieces are clamped once to complete grinding;

Processing accuracy is controlled within ± 0.004mm, batch consistency is better;

With automatic grinding wheel and automatic compensation function.

solution

Equipped with X / Z / C axis, C axis as indexing axis, follow-up grinding using G87 command;

The X axis is equipped with high resolution grating ruler to ensure the repeated positioning accuracy of the machine tool to ensure product consistency;

The C axis is equipped with a circular grating or uses a high-resolution servo motor.

Application effect

The use of the machine tool has got rid of the limitation of the original grinding by the fixture, and is no longer limited to the fact that the fixture can only grind one kind of workpiece, which solves the problem of unstable machining accuracy caused by the influence of the fixture accuracy;

The machine tool can freely select the corresponding eccentricity according to the customer's order requirements, which greatly improves the advantages of the traditional machine tool in the proofing of the new order (the traditional machine tool needs to make the fixture first);

The addition of grating ruler has greatly improved the repeated positioning accuracy of the machine tool, and the product consistency control is better.

USD

USD