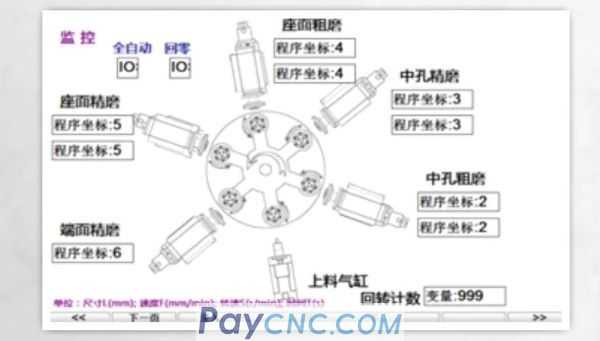

GSK 986Gs six-channel multi-station grinding

GSK986GS new platform CNC system is a new generation of wear-through CNC system launched by Guangzhou CNC. It adopts dual CPU architecture and supports multi-task operation, multi-channel, secondary development, flexible production configuration (network, interconnection) and other functions.

The standard configuration is 4 axes and 3 linkages, which can be expanded up to 6 channels and 10 feed axes;Motor equipped with absolute encoder;

The highest speed is 60000mm / min, the highest speed and high precision;

Super strong program instruction processing ability, preprocessing speed can reach 1000 / s;

The interpolation cycle is 1ms and the control accuracy is 0.1um / 0.0001 °.

In order to meet the needs of efficient production, the new platform CNC system of GSK986GS has developed six-channel functions to meet the needs of customers. It can simultaneously meet the six-station seat / face grinding and middle hole grinding. Compensation, program conversion for grinding process, workpiece quality management, machine tool status monitoring, fault self-diagnosis and abnormal alarm and other comprehensive processing control functions, the operation input interface is simple and convenient. The six-channel function control interface has many user-defined functions, which can be defined according to the needs of customers to improve the user experience.

Multi-axis multi-channel control 01

Spindle synchronous control, realizing dynamic exchange of targets, etc .; feed axis synchronous control, coordinating strongly coupled multi-input / output control objects; multiple channels executing in parallel, realizing one system to control multiple machine tools or multi-station machining; each The channel controls each axis to realize asynchronous control of special machine tools.

Six channel interface customization 02

The six-channel work operation interface can be customized, and the definition of each station can be edited according to user needs, making the operation simple and easy to understand.

Information management, CNC can be equipped with standard TCP / IP to connect with computer. Through online factory management (interconnection), data transmission, simple control of machine tools and reading of processing information are realized.

Machine tool automation is an industry trend in the field of grinding. The 986GS new platform CNC system should provide a complete machine tool automation solution to this trend. It can provide a two-channel truss manipulator solution, and can also provide a robot control solution according to the actual needs of customers. Measuring devices such as measuring instruments can automatically record and detect data such as dimensions and tolerances.

USD

USD