GSK RB08 Robot Working Examples 5

The project is finished by polishing the outer surface of thin-walled stainless steel products.

solution

1 RB08 robot, matched with special loading bin and special rotary gripper, to achieve accurate positioning, grasping and polishing of incoming blanks;

Design a set of arranged loading trays to meet the rough positioning of incoming materials.

Application effect

Robot loading and unloading system is very convenient to change models;

The robots run alternately, and the appearance is consistent. The grinding action is closely coordinated and the operation is smooth.

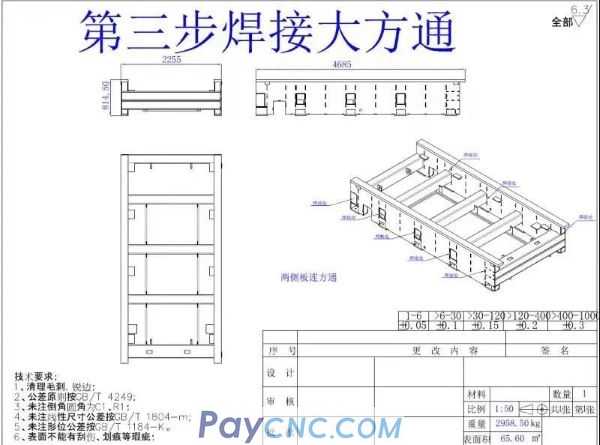

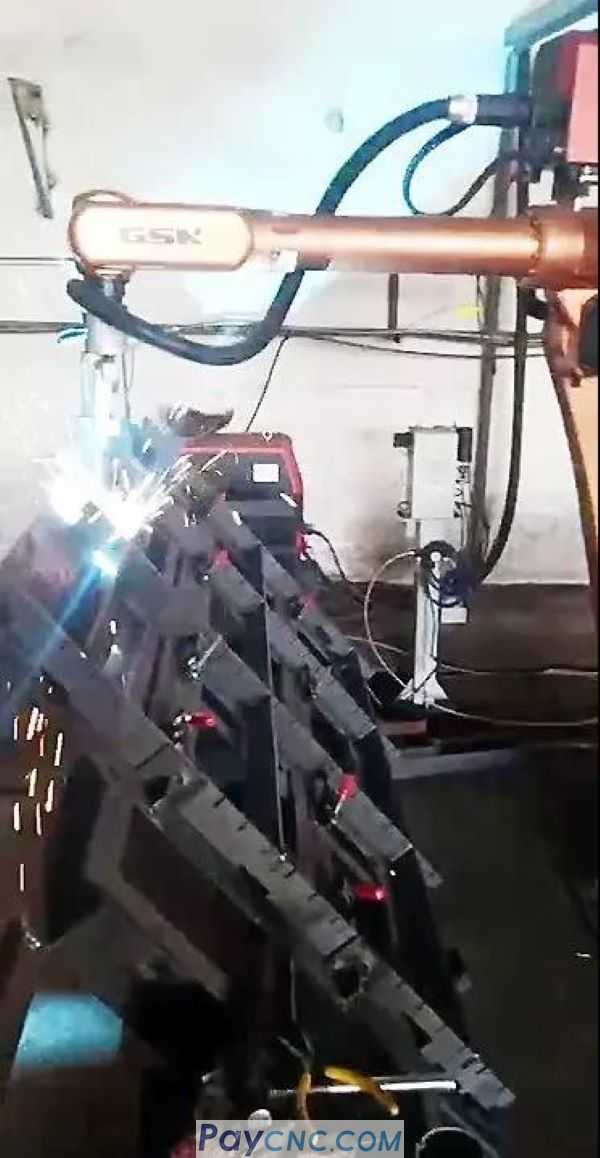

GSK-RB08A3 robot Application of Dafangtong Welding

The robot replaces the welder's welding, and the workpiece is manually loaded and unloaded, and the welding is completed in one clamping;

The maximum width of the workpiece is 2255mm, the maximum length is 4865mm, and the minimum wall thickness is 3mm.

solution

The project consists of a RB08A3 welding robot, a gun cleaning and wire cutting mechanism, a set of welding tools, an automatic welding power source, and an automatic anti-collision welding gun.

Due to the long workpiece, the project uses RB08A3-1840 robot;

In order to ensure the stability and continuity of welding, the project is equipped with a cleaning gun wire cutting mechanism.

Application effect

The tooling realizes one-time clamping of the workpiece, and the two robots perform diagonal welding to effectively control the amount of deformation;

The welding industry is a high-risk industry. High temperature, arc light, and welding fumes have a certain impact on the physical and mental health of workers. The application of welding robots in the welding industry is a general trend. This is both a market promotion and a requirement for technological upgrade.

GSK RB08 robot used Kettle stamping connection

Use robot to complete automatic kettle punching to realize rough and fine punching automation;

There are two kinds of specifications. Welding wire position needs to be identified for rough punching and process hole position must be identified for fine punching.

Adapt to two molds, use two hands to grasp, complete two pieces of loading and unloading at one time.

solution

5 punches, 7 RB08 robots, robot claws, welding wire positioning device, dual workpiece feeding and feeding lines, and rough feeding of bottles;

Five punches, seven RB08 robots, a robot base, a process hole positioning device, a single workpiece loading and unloading conveyor line, and a fine-pitching kettle.

Application effect

Realize automatic and thick blanking process of hot water bottle, stable quality, and solve labor gap.

USD

USD