GSK RB08 Robot Working Examples 6

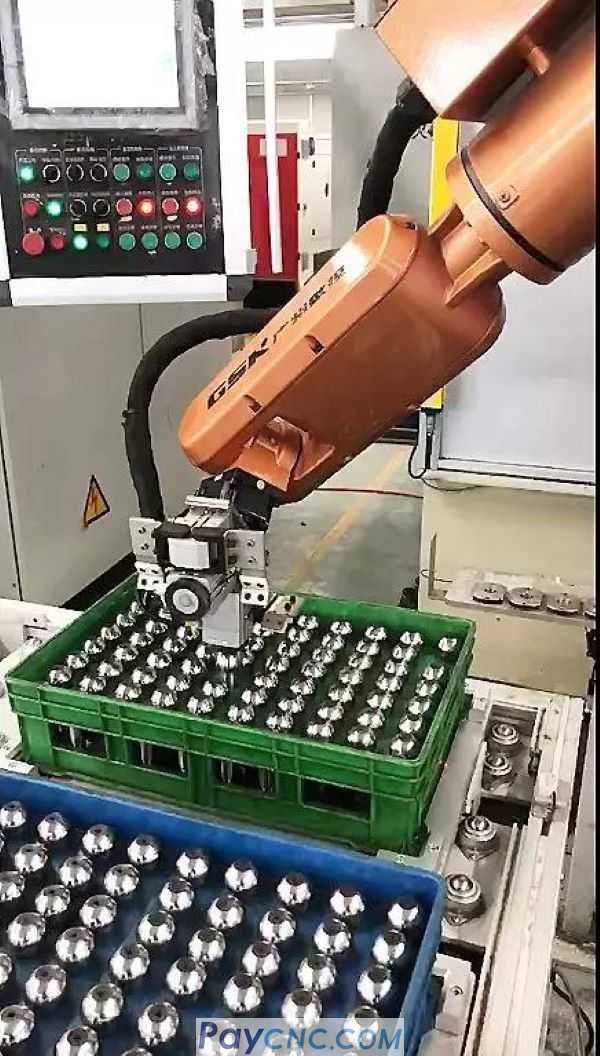

GSK RB08 robot for valve body loading and unloading

Robot instead of manual loading and unloading;

The larger the storage capacity of the upper and lower silos, the lower the cost;

For every 15 workpieces processed, one workpiece is sent out as a sample for inspection.

solution

The loading silo adopts a large planar structure, which is placed manually, and the robot arm automatically shifts and grabs, which has low cost;

The laser sensor is used to detect the pin hole on the workpiece to identify the workpiece direction;

Manipulator automatic palletizing and unloading, manual timing collection mode;

Above the loading bin, a sampling inspection table is set to place the workpieces to be inspected.

Application effect

Manipulator instead of manual, can work continuously and stably, avoiding manual work in dusty environment for a long time;

It can identify the workpiece with wrong loading orientation, avoiding the damage caused by manual error.

The cost is low, and the cost can be recovered within one and a half years.

RB08 stainless steel cover sanding and polishing application

The project is finished by polishing the outer surface of thin-walled stainless steel products.

solution

1 RB08 robot, matched with special loading bin, workpiece positioning and rotating device, grinding disc gripper, to achieve accurate positioning, grasping and polishing of incoming blank

Design a set of adjustable tray lever feeding tray to meet the rough positioning of different incoming materials. The blank is simple and convenient to feed.

Application effect

The robot's gripping action is stable, the application of the workpiece positioning device is stable, and the grinding system runs smoothly;

The robot runs alternately, the grinding action cooperates closely, and the appearance consistency is good.

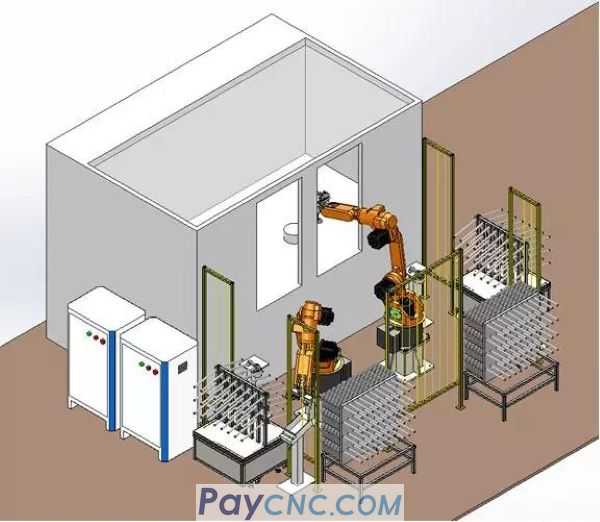

GSK RB08 robot used Loading and unloading of quenching machine

The robot replaces the human, and completes the loading and unloading of the double-station quenching machine;

Convenient for manual replenishment and replenishment, the frequency of artificial replenishment is not higher than 1h / time

With the first quality inspection function, it will enter normal production after manual confirmation.

GSK RB08 robot used Loading and unloading of quenching machine

The robot replaces the human, and completes the loading and unloading of the double-station quenching machine;

Convenient for manual replenishment and replenishment, the frequency of artificial replenishment is not higher than 1h / time

With the first quality inspection function, it will enter normal production after manual confirmation.

solution

4 RB08 handling robots, equipped with two double station hardening machines. According to the different types of workpieces, the ball head workpiece unit is equipped with a circulating material bin, a workpiece positioning table, and a quality inspection table; the joint unit is equipped with a hanging magazine, a workpiece positioning table, a quality inspection table, and a hanging lower bin;

The robot completes the automatic operation of taking the workpiece-positioning the workpiece-clamping the workpiece-quenching-unloading.

Application effect

Adopt manual adjustment and change of production mode, and solve the problem of multi-model and small batch production with less transformation cost

Reduce labor intensity, work stably, and maximize efficiency.

USD

USD