GSK RB15L Robot Examples 02

GSK15L robot used in motorcycle engine box automatic production line

The robot replaces the manual operation of the left box cover and the right box cover with blowing and loading and unloading;

The left cover has completed 5 processes, and the right cover has completed 4 processes.

solution

3 independent processing units, left processing unit, right processing unit, middle processing unit;

Three RB15L transport robots pick up the workpiece from the slide table, perform chip blowing of the workpiece, and load and unload the machining center.

Application effect

The robot can replace the human, and can work 24 hours to complete the task steadily;

Reduce labor and labor intensity.

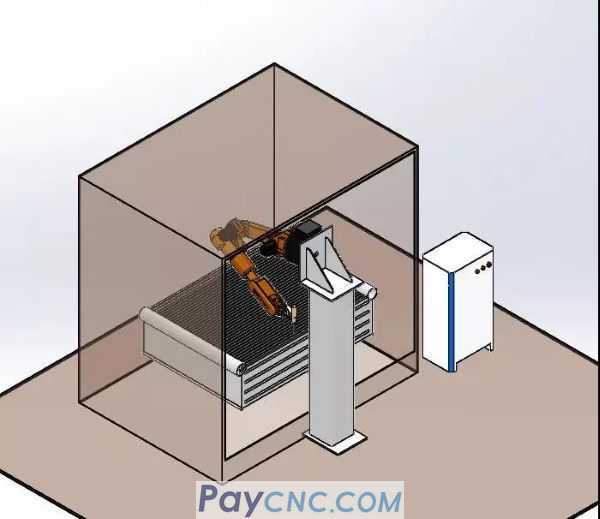

GSK RB15L robot is used to load and unload curtain wall materials

Replacing the original manual production method, avoiding quality problems originally caused by operator differences, improving product stability and reliability, reducing customer complaints, and achieving the purpose of reducing costs and increasing efficiency.

solution

A GSK RB15L robot is equipped with sawing machine equipment, machining center equipment, conveying mechanism, secondary positioning mechanism, feeding platform or feeding line to complete the automatic processing of the workpiece.

Application effect

The robot replaces the human, and can work 24 hours a day, stably completing the task.

GSK RB15L robot for dusting

Robot replaces human and completes automatic dusting operation;

Mesh sheet metal parts, the largest workpiece is about 2000 * 1500 * 520mm.

solution

1 RB15L handling robot, side-mounted, equipped with automatic spray gun to complete the powder spraying operation.

Application effect

The dusting quality of the workpiece is stable and the consistency is good, which avoids manual operation in the dust environment.

USD

USD