GSK RB20 Robot Examples 01

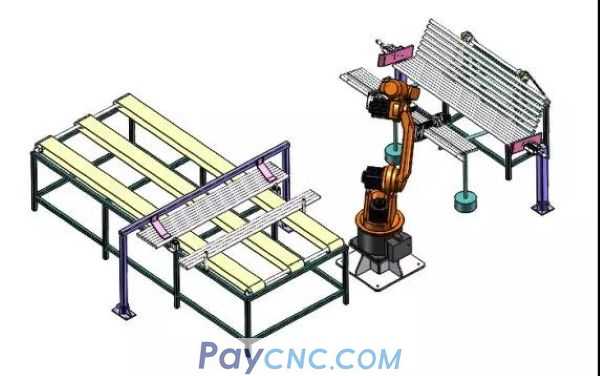

GSK RB20 robot Application of Light Tube Manufacturing Line

The robot replaces humans to sort the glass lamps, and realizes the automatic and stable production of reciprocating and rapid conveying and sorting;

The robot grabs the glass tube from the conveying line and puts it into the plastic cutting machine;

Production speed: 0.8 seconds / piece, continuous production for 24 hours.

solution

Adopt a RB20 handling robot, cooperate with a pipe cutting conveyor line, a sorting and positioning device, and a feeding conveyor to complete the automatic trimming, sorting, and high-temperature forming manufacturing process of neon tubes;

The robot hand grip adopts a flexible design. For different tube diameters, it can adaptively adjust the clamping force and position to achieve compatibility with all workpieces. At the same time, 20-30 pieces of lamp tubes can be loaded and unloaded.

The sorting and positioning device is designed with automatic sorting lamps, shaping positioning and sorting functions, to prevent pinching and falling abnormalities.

Application effect

The robot replaces the human, and can work continuously for 24 hours to complete the task steadily;

The glass manufacturing industry is a certain dangerous industry, especially high temperature and efficient production, glass fragments and dust, etc., which have a certain impact on the working environment and physical and mental health of workers. The use of robots can avoid various accidents and provide production efficiency ;

Experts believe that the application of robots in the glass manufacturing industry is a general trend, which is not only a market promotion, but also a requirement for the upgrading of production technology.

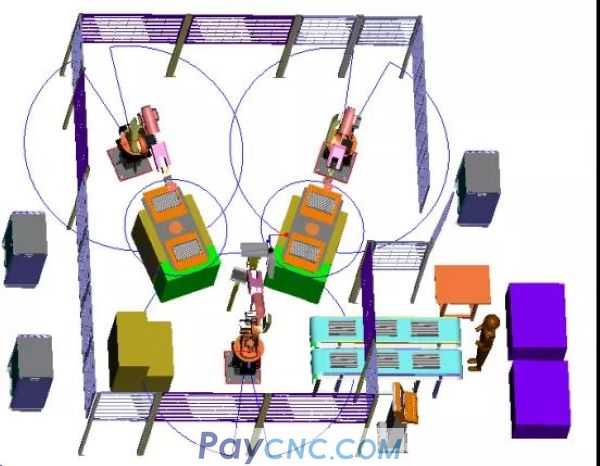

GSK RB20 Robot Aluminum Die Casting Filter sanding and deburring applications

Robots replace humans to complete the polishing of aluminum die-casting filters, loading and unloading machines, and workpiece conveyance;

The grinding of the entire 120S workpiece is completed, and all risers and burrs around the workpiece are cleaned after grinding.

solution

Adopt double station design to solve the problem of compact production cycle;

One RB20 robot is used to transfer and unload, two RB20 robots are used to polish the workpiece, and the commutation device is designed to transfer, so that three robots can complete the grinding and polishing of the front and back of the workpiece

Design a multi-purpose robot grinding tool to meet the grinding tasks of different positions of the workpiece.

Application effect

Improve the efficiency of optimized processing technology by 50%;

Reduced and reduced tool wear;

The finished surface finish has been significantly improved.

GSK RB20 Robot Radiator Grinding Application

Robots are used instead of manual grinding, and 16 grinding workpieces are installed manually at one time

Maximum deformation of workpiece grinding surface: <0.1mm

80 # sandpaper on the surface of the workpiece to grind the messy pattern, the beat is <12S / workpiece.

solution

Set up two stations, and manual loading and unloading are set outside the robot's operating range, so that robot grinding can be performed simultaneously with manual loading and unloading to ensure manual safety;

Considering the beat and efficiency, the entire plate workpiece 6 ~ 8 workpieces are polished at the same time, and the manual loading and unloading levels are synchronously loading and unloading and quality inspection;

The positioning pin is set on the workpiece positioning fixture to realize the rapid replacement of different models of fixtures and improve the efficiency.

Application effect

The robot replaces the human, and can work continuously for 24 hours to complete the task steadily;

The sanding industry is a certain dangerous industry, especially polishing sanding dust, such as abrasion of sandpaper and stone, metal dust and so on. These dusts have a certain impact on the physical and mental health of workers, and the use of robots can avoid various accidents;

Robots are used instead of manual for grinding work. The workpiece has a good surface consistency and quality stability; it will not affect the product quality because of the workers' technical proficiency and work attitude;

Grinding experts believe that the application of robots in the casting industry is the general trend, which is not only a market promotion, but also a requirement for technological upgrading.

USD

USD