GSK RB20 Robot Examples 02

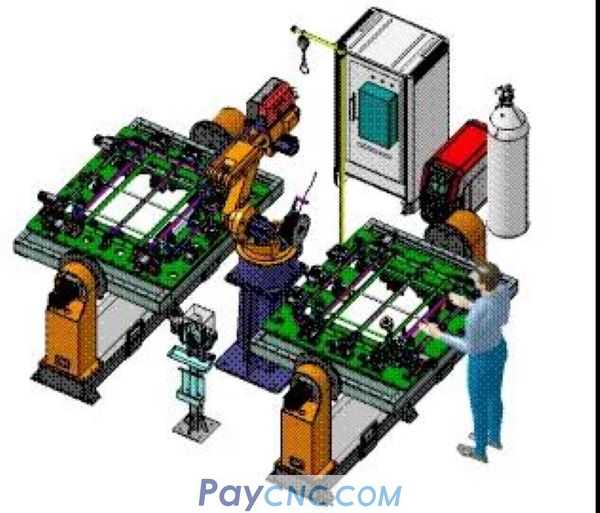

GSK RB20 robot Application in support welding

Incoming parts from customers, manual loading and unloading;

Automatic fixture positioning and clamping of the workpiece, robot replaces manual welding;

All workpieces can be welded in a range of more than 95% of the weld can be normally welded without interference;

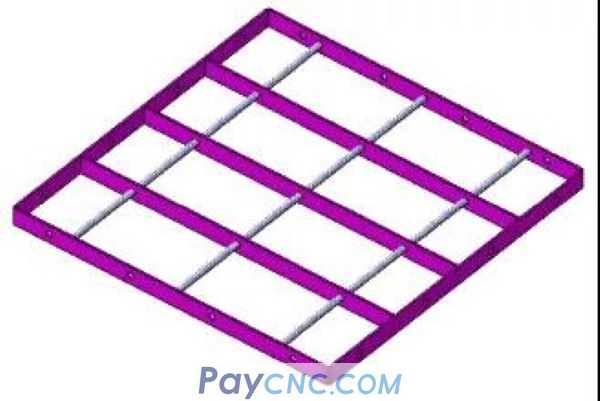

The welding fixture should be able to accommodate the clamping of two different workpieces.

solution

Welding station solution using two single-axis positioners and one robot;

Workers loading and unloading manually;

The fixture automatically clamps and positions the workpiece, and one RB20 welding robot welds the workpiece after clamping and positioning;

At the same time, the worker can carry out the loading and unloading operation on the other side, and this cycle.

Application effect

Robots replace humans, which can ensure that each welding is consistent and has a better welding effect;

The use of automatic fixtures to clamp workpieces can ensure consistent positioning accuracy every time;

The welding industry is a certain dangerous industry, especially welding arc light, smoke powder, and high-temperature efficient production. It has a certain impact on the working environment and physical and mental health of workers. The use of robots can avoid various accidents and provide production efficiency. .

RB20 Automotive Cylinder Block Automatic Grinding Application

Docking with Party A's existing equipment to achieve automatic grinding and deburring of workpieces;

The total time for workpiece loading and unloading and deburring is below 85S.

solution

Design a brand new automatic roller line, apply the robot to clean the burr directly on the roller line, eliminating the burr cleaning process of the deburring machine;

Automatic roller line design incoming material guide device to correct and guide the workpiece to the same material;

The automatic roller conveyor line is provided with 3 blocking positioning devices, which implement logical control with the supporting induction device to separate the adhered workpieces;

A high-power speed-regulating motor and a special flexible disc brush are used to perform burr cleaning on the working surface of workpiece 3, and the robot performs a grinding process on the entire plane, so that all burrs on the processing surface can be effectively cleaned.

Application effect

The robot grinding unit completed the burr cleaning task of 1 workpiece in 57 seconds, and the workpiece burr cleaning effect is excellent;

Achieved long-term stable production and greatly improved product quality and increased production capacity;

It solves the problems of many grinding labors and heavy handling operations in the grinding process of the production line.

RB20 medical device parts Sanding and polishing applications

Replace the manual polishing of the outer surface of aluminum medical device parts;

After grinding the outer surface of aluminum products, the butt joint is smooth and flat.

solution

1 RB08 robot, matched with a set of special feeding and grinding robot grippers, to achieve blank loading and unloading, grinding and polishing;

Design a set of arranged loading trays to meet the rough positioning of incoming materials, and the blanks are simple and convenient to load;

Design a set of rotating disk positioning device to match the automatic rotation of the robot to achieve precise displacement of the workpiece;

Design a set of sandpaper changing mechanism to realize the function of automatic sandpaper changing in the process of robot grinding and polishing

Application effect

The robot's gripping action is stable, and the grinding system runs smoothly;

The robot runs alternately, the grinding action cooperates closely, and the appearance consistency is good.

USD

USD