How to calculate workpiece cost

Cost control is one of the ways for an enterprise to reduce costs and increase efficiency. The workpiece processing procedures are complicated, how can we calculate the effective cost of the workpiece? Read through the following, you will have the essence of calculating cost, look carefully.

When the material cost is constant, the main difference lies in the different labor costs, transportation costs, consumption costs, and taxes of each company. Then, in what way are these parts of the machining factories calculated?

The following editor has compiled part of the information for reference (the calculation method is different due to the price of different places).

>>>>

Detailed calculation method

1. First, you can ask the other party to provide preliminary process arrangements for key or complex parts, detailing each process and the time consumption of each process.

2. The processing cost can be calculated according to the hourly cost of the equipment required for each process. You can also ask the supplier for the specific equipment cost. For example, ordinary Lijia is between 60 and 80 yuan per hour (tax included); ordinary equipment such as milling machines and general vehicles is generally 30 yuan.

3. Add packaging and transportation, management costs, tooling and tools, and profit in proportion to the price. Of course, the price will have a lot to do with the annual purchase volume and difficulty of the part to a certain extent. The price difference between single piece and batch is very easy to understand.

>>>>

Rough estimation

1. For large items, the volume is larger and the weight is heavier.

The difficulty is average: the ratio of the processing cost to the cost of the raw materials of the entire part is about 1:1, and this ratio is inversely proportional to the purchase amount.

The more difficult one: The ratio of processing cost to the cost of the entire part's raw materials is about 1.2~1.5:1, which is inversely proportional to the purchase amount.

2. For small and medium items

General difficulty: The ratio of the processing cost to the cost of the raw materials of the whole part is about 2~3:1, and this ratio is inversely proportional to the purchase amount.

More difficult: The ratio of processing cost to the cost of raw materials for the entire part is about 5-10:1, and this ratio is inversely proportional to the purchase amount.

Because machining has great process flexibility, that is, a part can have many kinds of process arrangements, the cost is of course different, but sometimes the supplier will tell you a complicated process to increase the price when quoting, but the actual production Other simple processes are sometimes used, so the purchaser's own reading of drawings and knowledge of parts processing determines your grasp of the cost, so the purchase of mechanical parts requires more comprehensive mechanical processing knowledge.

>>>>

Machining costs are generally based on working hours

If you want to process a work piece, first it is the material cost of the other party; then some travel expenses to purchase the work piece (generally not).

The most important thing is the processing man-hours required for the workpiece you want to process. The general lathe worker is 10-20 yuan/hour, and the fitter needs about 10-15 yuan/hour; the rest are not listed.

If there are no ready-made tools (such as knives, molds), you also need to bear part or all of the purchased costs; the final total is the processing costs you have to pay!

Material costs, machine depreciation, labor costs, management fees, taxes, etc. are basically required. Or material costs, processing fees and taxes, as well as business costs, transportation costs, and budgeting requires a thorough understanding of the market. If you don’t do it for a few years, you will not get the idea.

Process issues should include material costs, processing fees (which processing prices are different), equipment depreciation fees, worker wages, management fees, taxes, etc. The main thing is to first determine the process, that is, the processing method, and then calculate the man-hours based on the process. The man-hours determine the basic processing cost of a single part, plus other costs. Craftsmanship is a very complicated science, and a part adopts different crafts, and the price is different.

>>>>

Basic cost

In fact, the price of working hours for various types of work is not fixed. It will vary according to the difficulty of the workpiece, the size of the equipment, and the performance. Of course, the key depends on your quantity, but generally speaking, it has a basic price. Floating between basic prices.

1. The basic price of the car: 20-40 yuan

The specifics depend on the actual situation, like small items, the simple working hours are less than 20 yuan; sometimes even only 10 yuan.

For example, some large pulleys have a large machining allowance, and the boss can only earn money for cast iron powder; sometimes if the workpiece is large, it can be higher than the one that cannot be processed on the market, two or three times, and others can't help it.

2. Basic price of grinding: 25~45 yuan

3. Basic price for milling: 25~45 yuan

4. Basic price of drill: 15~35 yuan

5. Basic price for planing: 15~35 yuan

6. The basic price of wire cutting: 3~4 yuan/900 square millimeters

7. The basic price of EDM: 10-40 yuan, a single piece is generally 50 yuan/piece (less than 1 hour)

8. The basic price of NC: 2~4 times more expensive than ordinary ones. Click to receive 10G CNC programming tutorial for free

9. Carving: Generally, it is a single piece, 50~500 yuan/piece. Of course, it is still a word, the specific price of the specific product.

The above prices are for reference only. If you have any experience, I hope you can also tell us about it.

Due to different regions, different times, different manufacturers, different buyers, different suppliers, different quantities, there are many differences, and the prices are also very different, not fixed. However, it is generally charged according to the processing hours, and a reference is given as follows (the figures are only for reference, the difference in region and time is very large, this data does not include electrical processing, such as wire cutting, which is generally charged based on the processed area).

>>>>

About the charging standard of general machined parts

1. The method of recording the price by working hours:

Z25 drilling machine, CA6140 lathe, planer, slotting machine, sawing machine are charged at 15 yuan per hour. Vertical and horizontal milling, wire cutting, large lathe, and gantry milling are charged at 20 yuan per hour. The fitter generally charges 15 yuan per hour for maintenance. The timekeeping unit starts from taking over the processing to the end of the processing and acceptance.

2. According to the requirements of parts, quantity and accuracy:

(1) General materials for drilling and processing

The depth-to-diameter ratio is not more than 2.5 times and the diameter is less than 25mm according to the drill diameter * 0.05, and the diameter 25 to 60 is based on the drill diameter * 0.12 (the smallest hole is not less than 0.5 yuan).

The base price for general materials with a depth-to-diameter ratio greater than 2.5*depth-to-diameter ratio*0.4 is charged. The base price*5 is charged for those with an aperture accuracy requirement of less than 0.1mm or a center distance requirement of less than 0.1mm.

The charging standard for tapping is charged according to the diameter of the tap *0.2 (cast iron as the standard, steel parts *1.2), and the standard base price *0.2~0.8 during batch processing (according to the batch size and processing difficulty).

(2) General precision optical axis processing for lathe processing

If the ratio of length to diameter is less than 10, the charge will be charged according to the size of the processed part*0.2 (minimum 5 yuan).

If the aspect ratio is greater than 10, the base price of the general optical axis * the number of aspect ratios * 0.15, and the accuracy required to be within 0.05mm or the tapered ones are charged at the base price of the general optical axis *2.

General stepped shafts (fan shafts, pump shafts, reducer shafts, grinding wheel shafts, motor shafts, spindles, etc.) are processed at the base price of general precision optical shafts*2 If the stepped shafts have tapers, inner and outer ribs, they are processed according to general precision optical shafts. Base price*3 charged.

General-purpose lead screws are charged at the base price of general precision optical axis processing*4.

Generally, the charging standard for flange parts is charged according to the material diameter*0.07, and the diameter larger than 430mm is charged according to the material diameter*0.12.

General round nut parts are charged at diameter * 0.25 (including materials).

Generally trapezoidal, triangular nut parts are according to diameter * 0.3 (material not included).

General shaft sleeve parts (diameter less than 100 and diameter-length ratio less than 2) are charged according to the outer diameter of the material *0.2, and the diameter-length ratio exceeds 2 according to the diameter-length ratio * base price * 0.6.

Generally, if the wear of bearing platform parts is less than 2mm in diameter, less than 40mm in width, and less than 25mm, each is 5 yuan, and the center frame is required, or the base price of the length greater than 1.7 meters*2 is charged. If the diameter is greater than 40mm, it will be charged as diameter*0.2.

(3) General keyway processing for milling machine processing

(If the aspect ratio is less than 10), the key slot width *0.5 is charged (minimum 5 yuan). If the aspect ratio exceeds 10, it will be charged at the aspect ratio*base price*0.1.

If there is a strict location requirement, it will be charged at the base price*2.

The processing of materials with hardness greater than HRC40 is charged at the base price*2.

General spline processing (length-to-diameter ratio is less than 5) is charged according to the outer diameter of the spline shaft *0.8 (minimum 15 yuan).

General gear processing is charged at module * tooth number * 0.5 yuan. Worm gear is charged at base *1.2. Helical gears, bevel gears, and shift gears are charged at the base price*2. Click to receive 10G CNC programming tutorial for free

General plane processing is charged at 1.5 yuan per square decimeter (minimum 5 yuan).

Generally, boring is charged according to the hole diameter*0.25.

(4) Band saw processing

For general round steel, thick-walled pipe, and square steel cut, it is calculated at 5 yuan per square decimeter (minimum 5 yuan), and general steel plate is cut and split, and the opening angle is 10 yuan per square decimeter (minimum 10 yuan).

(5) Wire cutting processing

General parts are charged according to the cut-off area (square millimeter) * 0.008 yuan. The parts that need to be threaded are priced 5 yuan for each threaded hole.

(6) Electric welding and gas cutting and plasma cutting

Ordinary welding rod with a diameter of 3.2 yuan is 1 yuan, and TH506 welding casting is 3 yuan. For gas cutting processing, plasma cutting stainless steel is calculated according to the thickness of the iron plate mm*cutting length m, and it is charged at the base price of gas cutting*3, and the carbon steel is charged at the base price of gas cutting*2.

(7) Regarding special urgent and overtime work

Special urgent parts charged at standard base price*2 are defined as: arranging repairs or manufacturing urgent parts for a specific customer as soon as possible. Overtime parts refer to parts that must be manufactured continuously beyond normal working hours.

Optical tool curve grinding processing fee is 60 yuan/hour,

200 lathe, 20 yuan/hour,

For lathes over 300, RMB 30/hour,

Milling machine 20 yuan/hour, drilling 15 yuan/hour,

Boring machine 35 yuan/hour,

The grinder is 30 yuan/hour,

Slotting bed 15 yuan/hour,

Bull head planer 20~25 yuan/hour,

Longmen planing and milling 30 yuan/hour,

Rolling machine (rolling steel plate with thickness below 20) 60 yuan/hour,

C620.C6140 is basically 20 yuan an hour,

30 yuan per hour for 30 lathes,

The vertical lathe is 60 yuan per hour,

Radial drill is 20 yuan an hour,

T68 boring machine is 30 yuan per hour,

Niu planing small vertical milling and horizontal milling is 20 yuan an hour,

Longmen milling and planing are 60 yuan an hour,

400 flat grinding and cylindrical grinding machine under one meter are 20 yuan per hour,

It is 60 yuan per hour for three meters away,

The machining center is 80 yuan an hour (the same as counting milling and counting cars),

Electric welding and gas cutting are basically calculated by pieces, if it is not convenient to calculate, it is calculated at 30 yuan per hour.

Fitter assembly is 20 yuan an hour.

In addition, the labor payment is also related to the amount of outsourcing processing. The price of fine processing hours:

Fine grinding tolerance 0.005, 40 yuan/hour,

Spark tolerance 0.01, 80 yuan/hour,

Slow wire tolerance 0.005, 100 yuan/hour,

Smooth grinding, tolerance 0.003, 180 yuan/hour.

(7) CNC punching cost calculation:

0.06 yuan/second for large batches (216 yuan/hour)

Medium batch at 0.08 yuan/second (280 yuan/hour)

Small batches are charged at 0.1 yuan/second (360 yuan/hour).

The steel plate specification for mass production typesetting is 1219mm*243mm. The copper plate specification is 600mm*1500mm.

Impact frequency: 3 times/sec (gap 25mm)

2 times/sec (gap 112mm)

1 time/second (gap 325mm)

Selection time: 3.0 seconds (average)

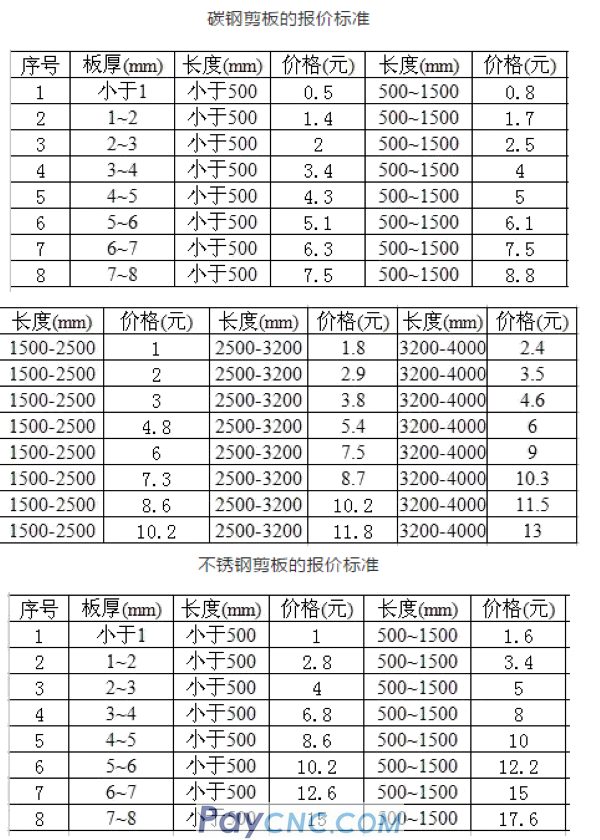

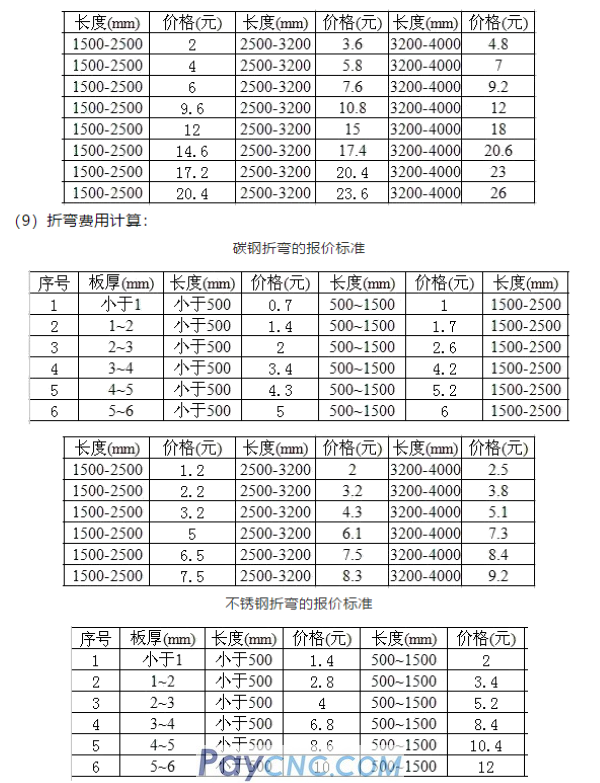

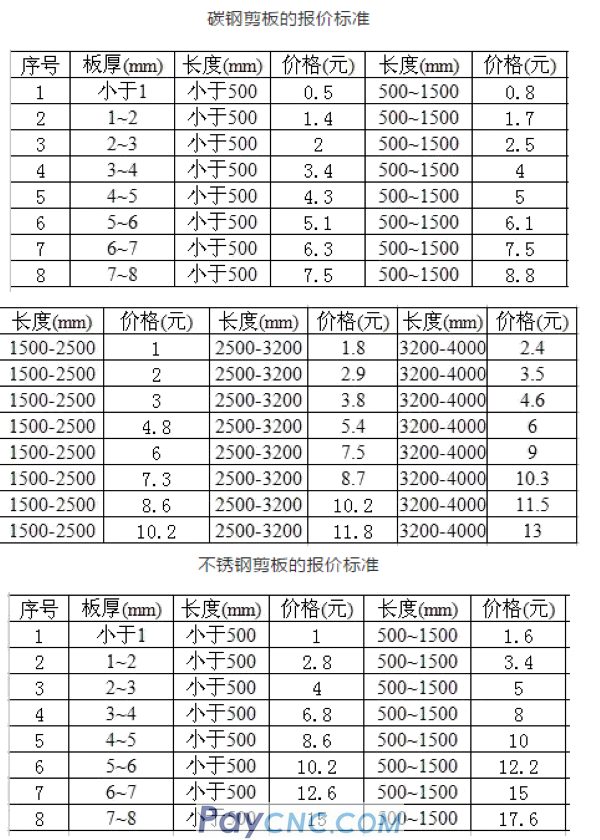

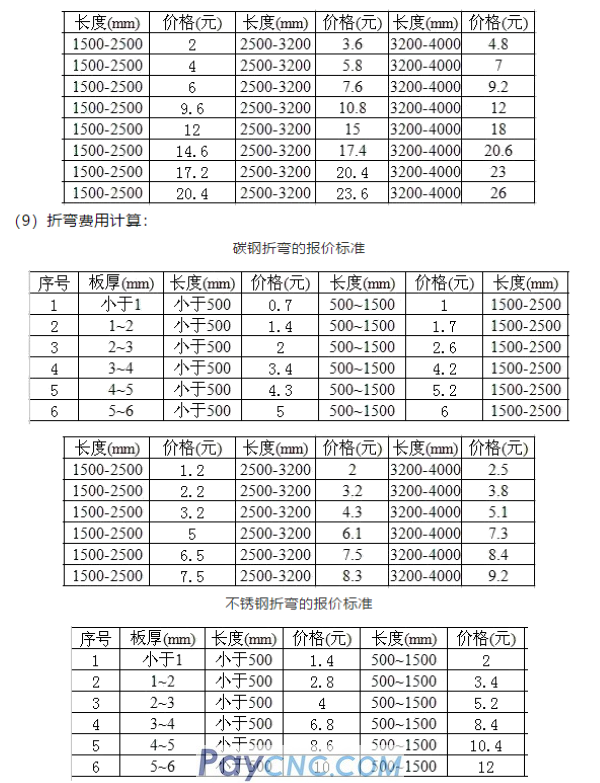

(8) Calculation of cutting cost of shearing machine:

Quotation Standard for Carbon Steel Shear Plate

(10) Cost calculation of angle shearing machine:

Each cut for large batches is: 0.1 yuan/cut.

Each cut for medium batch is 0.2 yuan/cut.

Each cut for small batch is 0.3 yuan/cut.

(11) Welding (argon welding, wire welding, butt welding) cost calculation:

Large quantities of welding per spot: 0.1 yuan/point, continuous welding: 0.1 yuan/cm.

For medium batches, each spot welding pressure is 0.15 yuan/point, and the continuous welding pressure is 0.15 yuan/cm.

Small batch welding per spot: 0.2 yuan/point, continuous welding: 0.2 yuan/cm.

(12) Cost calculation of ordinary punch (25T):

Ordinary punching machine can process punching, cutting angle, punching, riveting, pressing and other processes.

Each process in large quantities is processed according to: 0.1 yuan/process.

Each process of medium batch is 0.2 yuan/process.

Each process of small batch is processed according to: 0.3 yuan/process.

(13) Fitter cost calculation:

The fitter process includes tapping, drilling, countersinking, flanging, etc.

Each fitter process in large quantities is as follows: 0.1 yuan/process.

Each fitter process of medium batch is as follows: 0.2 yuan/process.

Each fitter process for small batches is as follows: 0.3 yuan/process.

(14) Calculation of polishing costs:

Polishing per point in large quantities: 0.1 yuan/point, continuous welding and polishing: 0.1 yuan/cm.

Polishing and welding per point for medium batch: 0.2 yuan/point, continuous welding and polishing: 0.2 yuan/cm.

For small batches, each point of welding and polishing: 0.3 yuan/point, continuous welding and polishing: 0.3 yuan/cm.

(15) Surface treatment cost accounting

Calculation of surface spray cost:

Large quantities of surface spray plastic press: 10 yuan / square meter. Less than 0.5 yuan is calculated as 0.5 yuan.

The medium-batch surface spray plastic press: 12 yuan/square meter. Less than 0.8 yuan is calculated as 0.8 yuan.

Small batch of surface spray: 15 yuan/square meter. Less than 1.0 yuan is calculated as 1.0 yuan.

Cost calculation of surface color zinc plating:

Color zinc plating on the surface: 2.5 yuan/kg. Outward processing, at market price.

Calculation of the cost of zinc plating on the surface:

White zinc plating on the surface: 2.5 yuan/kg. Outward processing, at market price.

Cost calculation for surface chrome plating:

Chrome plating on the surface: 15 yuan/kg. Outward processing, at market price.

Calculation of nickel plating cost:

Nickel plating on the surface: 10 yuan/kg. Outward processing, at market price.

Black nickel plating cost calculation:

Black nickel plating on the surface: 8 yuan/kg. Outward processing, at market price.

Surface chromization cost calculation:

The surface chromization is as follows: 70 yuan/square meter. Outward processing, at market price.

Black surface cost calculation:

If the surface is black, press: 2 yuan/kg. Outward processing, at market price.

Surface anodizing cost calculation:

Surface oxidation white press: 20 yuan/square meter. Outward processing, at market price.

The surface oxidation black press: 25 yuan/square meter. Outward processing, at market price.

Screen printing cost calculation:

A4 film production fee: 120 yuan / sheet. Outward processing, at market price.

The cost of making A4 stencil: 120 yuan/piece.

A4 silk screen is quoted according to the size of the area or the size of the complexity.

(16) Cost calculation of assembly and packaging

Calculation of assembly cost:

The assembly labor cost in the factory does not include the cost of fasteners and standard parts.

Large batch: 10 yuan/hour, medium batch: 15 yuan/hour, small batch: 18 yuan/hour.

Calculation of packaging costs:

The cost of packaging materials is calculated according to the actual consumption.

In-factory packaging labor for large batches: 13 yuan/hour, large batches: 15 yuan/hour, small batches: 18 yuan/hour Time.

In large quantities, the assembly and packaging costs are calculated based on the actual costs.

Under normal circumstances, the assembly fee, packaging fee, transportation fee, and scrap cost for medium and small batches are calculated at 15% of the material cost. The transportation fee only covers the Pearl River Delta.

(17) Calculation of transportation costs:

Please refer to the "Short-distance Transportation Price List" for the quotation of truck transportation costs.

Large quantities are calculated based on actual expenses.

Transportation fees for medium and small batches are calculated based on actual costs.

Long-distance transportation or export, the cost is extra.

(18) Calculation of scrap cost:

The calculation of mass scrap cost is as follows: scrap cost = single product material cost* (2%~5%).

When the material cost is constant, the main difference lies in the different labor costs, transportation costs, consumption costs, and taxes of each company. Then, in what way are these parts of the machining factories calculated?

The following editor has compiled part of the information for reference (the calculation method is different due to the price of different places).

>>>>

Detailed calculation method

1. First, you can ask the other party to provide preliminary process arrangements for key or complex parts, detailing each process and the time consumption of each process.

2. The processing cost can be calculated according to the hourly cost of the equipment required for each process. You can also ask the supplier for the specific equipment cost. For example, ordinary Lijia is between 60 and 80 yuan per hour (tax included); ordinary equipment such as milling machines and general vehicles is generally 30 yuan.

3. Add packaging and transportation, management costs, tooling and tools, and profit in proportion to the price. Of course, the price will have a lot to do with the annual purchase volume and difficulty of the part to a certain extent. The price difference between single piece and batch is very easy to understand.

>>>>

Rough estimation

1. For large items, the volume is larger and the weight is heavier.

The difficulty is average: the ratio of the processing cost to the cost of the raw materials of the entire part is about 1:1, and this ratio is inversely proportional to the purchase amount.

The more difficult one: The ratio of processing cost to the cost of the entire part's raw materials is about 1.2~1.5:1, which is inversely proportional to the purchase amount.

2. For small and medium items

General difficulty: The ratio of the processing cost to the cost of the raw materials of the whole part is about 2~3:1, and this ratio is inversely proportional to the purchase amount.

More difficult: The ratio of processing cost to the cost of raw materials for the entire part is about 5-10:1, and this ratio is inversely proportional to the purchase amount.

Because machining has great process flexibility, that is, a part can have many kinds of process arrangements, the cost is of course different, but sometimes the supplier will tell you a complicated process to increase the price when quoting, but the actual production Other simple processes are sometimes used, so the purchaser's own reading of drawings and knowledge of parts processing determines your grasp of the cost, so the purchase of mechanical parts requires more comprehensive mechanical processing knowledge.

>>>>

Machining costs are generally based on working hours

If you want to process a work piece, first it is the material cost of the other party; then some travel expenses to purchase the work piece (generally not).

The most important thing is the processing man-hours required for the workpiece you want to process. The general lathe worker is 10-20 yuan/hour, and the fitter needs about 10-15 yuan/hour; the rest are not listed.

If there are no ready-made tools (such as knives, molds), you also need to bear part or all of the purchased costs; the final total is the processing costs you have to pay!

Material costs, machine depreciation, labor costs, management fees, taxes, etc. are basically required. Or material costs, processing fees and taxes, as well as business costs, transportation costs, and budgeting requires a thorough understanding of the market. If you don’t do it for a few years, you will not get the idea.

Process issues should include material costs, processing fees (which processing prices are different), equipment depreciation fees, worker wages, management fees, taxes, etc. The main thing is to first determine the process, that is, the processing method, and then calculate the man-hours based on the process. The man-hours determine the basic processing cost of a single part, plus other costs. Craftsmanship is a very complicated science, and a part adopts different crafts, and the price is different.

>>>>

Basic cost

In fact, the price of working hours for various types of work is not fixed. It will vary according to the difficulty of the workpiece, the size of the equipment, and the performance. Of course, the key depends on your quantity, but generally speaking, it has a basic price. Floating between basic prices.

1. The basic price of the car: 20-40 yuan

The specifics depend on the actual situation, like small items, the simple working hours are less than 20 yuan; sometimes even only 10 yuan.

For example, some large pulleys have a large machining allowance, and the boss can only earn money for cast iron powder; sometimes if the workpiece is large, it can be higher than the one that cannot be processed on the market, two or three times, and others can't help it.

2. Basic price of grinding: 25~45 yuan

3. Basic price for milling: 25~45 yuan

4. Basic price of drill: 15~35 yuan

5. Basic price for planing: 15~35 yuan

6. The basic price of wire cutting: 3~4 yuan/900 square millimeters

7. The basic price of EDM: 10-40 yuan, a single piece is generally 50 yuan/piece (less than 1 hour)

8. The basic price of NC: 2~4 times more expensive than ordinary ones. Click to receive 10G CNC programming tutorial for free

9. Carving: Generally, it is a single piece, 50~500 yuan/piece. Of course, it is still a word, the specific price of the specific product.

The above prices are for reference only. If you have any experience, I hope you can also tell us about it.

Due to different regions, different times, different manufacturers, different buyers, different suppliers, different quantities, there are many differences, and the prices are also very different, not fixed. However, it is generally charged according to the processing hours, and a reference is given as follows (the figures are only for reference, the difference in region and time is very large, this data does not include electrical processing, such as wire cutting, which is generally charged based on the processed area).

>>>>

About the charging standard of general machined parts

1. The method of recording the price by working hours:

Z25 drilling machine, CA6140 lathe, planer, slotting machine, sawing machine are charged at 15 yuan per hour. Vertical and horizontal milling, wire cutting, large lathe, and gantry milling are charged at 20 yuan per hour. The fitter generally charges 15 yuan per hour for maintenance. The timekeeping unit starts from taking over the processing to the end of the processing and acceptance.

2. According to the requirements of parts, quantity and accuracy:

(1) General materials for drilling and processing

The depth-to-diameter ratio is not more than 2.5 times and the diameter is less than 25mm according to the drill diameter * 0.05, and the diameter 25 to 60 is based on the drill diameter * 0.12 (the smallest hole is not less than 0.5 yuan).

The base price for general materials with a depth-to-diameter ratio greater than 2.5*depth-to-diameter ratio*0.4 is charged. The base price*5 is charged for those with an aperture accuracy requirement of less than 0.1mm or a center distance requirement of less than 0.1mm.

The charging standard for tapping is charged according to the diameter of the tap *0.2 (cast iron as the standard, steel parts *1.2), and the standard base price *0.2~0.8 during batch processing (according to the batch size and processing difficulty).

(2) General precision optical axis processing for lathe processing

If the ratio of length to diameter is less than 10, the charge will be charged according to the size of the processed part*0.2 (minimum 5 yuan).

If the aspect ratio is greater than 10, the base price of the general optical axis * the number of aspect ratios * 0.15, and the accuracy required to be within 0.05mm or the tapered ones are charged at the base price of the general optical axis *2.

General stepped shafts (fan shafts, pump shafts, reducer shafts, grinding wheel shafts, motor shafts, spindles, etc.) are processed at the base price of general precision optical shafts*2 If the stepped shafts have tapers, inner and outer ribs, they are processed according to general precision optical shafts. Base price*3 charged.

General-purpose lead screws are charged at the base price of general precision optical axis processing*4.

Generally, the charging standard for flange parts is charged according to the material diameter*0.07, and the diameter larger than 430mm is charged according to the material diameter*0.12.

General round nut parts are charged at diameter * 0.25 (including materials).

Generally trapezoidal, triangular nut parts are according to diameter * 0.3 (material not included).

General shaft sleeve parts (diameter less than 100 and diameter-length ratio less than 2) are charged according to the outer diameter of the material *0.2, and the diameter-length ratio exceeds 2 according to the diameter-length ratio * base price * 0.6.

Generally, if the wear of bearing platform parts is less than 2mm in diameter, less than 40mm in width, and less than 25mm, each is 5 yuan, and the center frame is required, or the base price of the length greater than 1.7 meters*2 is charged. If the diameter is greater than 40mm, it will be charged as diameter*0.2.

(3) General keyway processing for milling machine processing

(If the aspect ratio is less than 10), the key slot width *0.5 is charged (minimum 5 yuan). If the aspect ratio exceeds 10, it will be charged at the aspect ratio*base price*0.1.

If there is a strict location requirement, it will be charged at the base price*2.

The processing of materials with hardness greater than HRC40 is charged at the base price*2.

General spline processing (length-to-diameter ratio is less than 5) is charged according to the outer diameter of the spline shaft *0.8 (minimum 15 yuan).

General gear processing is charged at module * tooth number * 0.5 yuan. Worm gear is charged at base *1.2. Helical gears, bevel gears, and shift gears are charged at the base price*2. Click to receive 10G CNC programming tutorial for free

General plane processing is charged at 1.5 yuan per square decimeter (minimum 5 yuan).

Generally, boring is charged according to the hole diameter*0.25.

(4) Band saw processing

For general round steel, thick-walled pipe, and square steel cut, it is calculated at 5 yuan per square decimeter (minimum 5 yuan), and general steel plate is cut and split, and the opening angle is 10 yuan per square decimeter (minimum 10 yuan).

(5) Wire cutting processing

General parts are charged according to the cut-off area (square millimeter) * 0.008 yuan. The parts that need to be threaded are priced 5 yuan for each threaded hole.

(6) Electric welding and gas cutting and plasma cutting

Ordinary welding rod with a diameter of 3.2 yuan is 1 yuan, and TH506 welding casting is 3 yuan. For gas cutting processing, plasma cutting stainless steel is calculated according to the thickness of the iron plate mm*cutting length m, and it is charged at the base price of gas cutting*3, and the carbon steel is charged at the base price of gas cutting*2.

(7) Regarding special urgent and overtime work

Special urgent parts charged at standard base price*2 are defined as: arranging repairs or manufacturing urgent parts for a specific customer as soon as possible. Overtime parts refer to parts that must be manufactured continuously beyond normal working hours.

Optical tool curve grinding processing fee is 60 yuan/hour,

200 lathe, 20 yuan/hour,

For lathes over 300, RMB 30/hour,

Milling machine 20 yuan/hour, drilling 15 yuan/hour,

Boring machine 35 yuan/hour,

The grinder is 30 yuan/hour,

Slotting bed 15 yuan/hour,

Bull head planer 20~25 yuan/hour,

Longmen planing and milling 30 yuan/hour,

Rolling machine (rolling steel plate with thickness below 20) 60 yuan/hour,

C620.C6140 is basically 20 yuan an hour,

30 yuan per hour for 30 lathes,

The vertical lathe is 60 yuan per hour,

Radial drill is 20 yuan an hour,

T68 boring machine is 30 yuan per hour,

Niu planing small vertical milling and horizontal milling is 20 yuan an hour,

Longmen milling and planing are 60 yuan an hour,

400 flat grinding and cylindrical grinding machine under one meter are 20 yuan per hour,

It is 60 yuan per hour for three meters away,

The machining center is 80 yuan an hour (the same as counting milling and counting cars),

Electric welding and gas cutting are basically calculated by pieces, if it is not convenient to calculate, it is calculated at 30 yuan per hour.

Fitter assembly is 20 yuan an hour.

In addition, the labor payment is also related to the amount of outsourcing processing. The price of fine processing hours:

Fine grinding tolerance 0.005, 40 yuan/hour,

Spark tolerance 0.01, 80 yuan/hour,

Slow wire tolerance 0.005, 100 yuan/hour,

Smooth grinding, tolerance 0.003, 180 yuan/hour.

(7) CNC punching cost calculation:

0.06 yuan/second for large batches (216 yuan/hour)

Medium batch at 0.08 yuan/second (280 yuan/hour)

Small batches are charged at 0.1 yuan/second (360 yuan/hour).

The steel plate specification for mass production typesetting is 1219mm*243mm. The copper plate specification is 600mm*1500mm.

Impact frequency: 3 times/sec (gap 25mm)

2 times/sec (gap 112mm)

1 time/second (gap 325mm)

Selection time: 3.0 seconds (average)

(8) Calculation of cutting cost of shearing machine:

Quotation Standard for Carbon Steel Shear Plate

(10) Cost calculation of angle shearing machine:

Each cut for large batches is: 0.1 yuan/cut.

Each cut for medium batch is 0.2 yuan/cut.

Each cut for small batch is 0.3 yuan/cut.

(11) Welding (argon welding, wire welding, butt welding) cost calculation:

Large quantities of welding per spot: 0.1 yuan/point, continuous welding: 0.1 yuan/cm.

For medium batches, each spot welding pressure is 0.15 yuan/point, and the continuous welding pressure is 0.15 yuan/cm.

Small batch welding per spot: 0.2 yuan/point, continuous welding: 0.2 yuan/cm.

(12) Cost calculation of ordinary punch (25T):

Ordinary punching machine can process punching, cutting angle, punching, riveting, pressing and other processes.

Each process in large quantities is processed according to: 0.1 yuan/process.

Each process of medium batch is 0.2 yuan/process.

Each process of small batch is processed according to: 0.3 yuan/process.

(13) Fitter cost calculation:

The fitter process includes tapping, drilling, countersinking, flanging, etc.

Each fitter process in large quantities is as follows: 0.1 yuan/process.

Each fitter process of medium batch is as follows: 0.2 yuan/process.

Each fitter process for small batches is as follows: 0.3 yuan/process.

(14) Calculation of polishing costs:

Polishing per point in large quantities: 0.1 yuan/point, continuous welding and polishing: 0.1 yuan/cm.

Polishing and welding per point for medium batch: 0.2 yuan/point, continuous welding and polishing: 0.2 yuan/cm.

For small batches, each point of welding and polishing: 0.3 yuan/point, continuous welding and polishing: 0.3 yuan/cm.

(15) Surface treatment cost accounting

Calculation of surface spray cost:

Large quantities of surface spray plastic press: 10 yuan / square meter. Less than 0.5 yuan is calculated as 0.5 yuan.

The medium-batch surface spray plastic press: 12 yuan/square meter. Less than 0.8 yuan is calculated as 0.8 yuan.

Small batch of surface spray: 15 yuan/square meter. Less than 1.0 yuan is calculated as 1.0 yuan.

Cost calculation of surface color zinc plating:

Color zinc plating on the surface: 2.5 yuan/kg. Outward processing, at market price.

Calculation of the cost of zinc plating on the surface:

White zinc plating on the surface: 2.5 yuan/kg. Outward processing, at market price.

Cost calculation for surface chrome plating:

Chrome plating on the surface: 15 yuan/kg. Outward processing, at market price.

Calculation of nickel plating cost:

Nickel plating on the surface: 10 yuan/kg. Outward processing, at market price.

Black nickel plating cost calculation:

Black nickel plating on the surface: 8 yuan/kg. Outward processing, at market price.

Surface chromization cost calculation:

The surface chromization is as follows: 70 yuan/square meter. Outward processing, at market price.

Black surface cost calculation:

If the surface is black, press: 2 yuan/kg. Outward processing, at market price.

Surface anodizing cost calculation:

Surface oxidation white press: 20 yuan/square meter. Outward processing, at market price.

The surface oxidation black press: 25 yuan/square meter. Outward processing, at market price.

Screen printing cost calculation:

A4 film production fee: 120 yuan / sheet. Outward processing, at market price.

The cost of making A4 stencil: 120 yuan/piece.

A4 silk screen is quoted according to the size of the area or the size of the complexity.

(16) Cost calculation of assembly and packaging

Calculation of assembly cost:

The assembly labor cost in the factory does not include the cost of fasteners and standard parts.

Large batch: 10 yuan/hour, medium batch: 15 yuan/hour, small batch: 18 yuan/hour.

Calculation of packaging costs:

The cost of packaging materials is calculated according to the actual consumption.

In-factory packaging labor for large batches: 13 yuan/hour, large batches: 15 yuan/hour, small batches: 18 yuan/hour Time.

In large quantities, the assembly and packaging costs are calculated based on the actual costs.

Under normal circumstances, the assembly fee, packaging fee, transportation fee, and scrap cost for medium and small batches are calculated at 15% of the material cost. The transportation fee only covers the Pearl River Delta.

(17) Calculation of transportation costs:

Please refer to the "Short-distance Transportation Price List" for the quotation of truck transportation costs.

Large quantities are calculated based on actual expenses.

Transportation fees for medium and small batches are calculated based on actual costs.

Long-distance transportation or export, the cost is extra.

(18) Calculation of scrap cost:

The calculation of mass scrap cost is as follows: scrap cost = single product material cost* (2%~5%).

USD

USD