How to repair thread on CNC lathe

First, the problem

When turning threads on a CNC lathe, you often encounter such problems: (1) The thread cutter is damaged halfway through the thread. (2) I want to change a high-speed precision turning tool with a thread finishing tool. (3) Remove the threaded car and measure it again, and find that the depth is not enough. When faced with these same problems, we are often helpless, because after changing the tool or re-clamping the workpiece, the thread cutter is difficult to align with the original spiral groove, the starting position is not accurate, and the teeth are always messy.

2. The principle of turning thread on CNC lathe

To solve these problems, we must first understand the principle of CNC lathe turning thread. To complete the thread cutting, the workpiece must be accurately turned one turn, and the tool feeds one lead. In order to achieve this, a spindle encoder is installed on the CNC lathe. Use its synchronous pulse as the cutting control signal of the turning point of the turning tool

The number of pulses given to the servo motor has a corresponding relationship with the spindle speed. However, there is no direct mechanical connection between the rotation of the spindle of the CNC lathe and the feed motion. Therefore, when reinstalling the tool or clamping the workpiece again, it is not so easy to make the tip of the tool cut along the original spiral groove.

3. Existing prevention measures

At present, when using CNC lathes to turn threads in enterprises, most of them use a machine tool for turning. Both coarse and fine are used—a knife and the same speed. If the knife breaks in the middle, do not remove the knife bar, and directly change the blade to prevent messy teeth. But if the rough car. The two tools of fine turning are turned separately or the parts are re-clamped, which brings about the problem of messy teeth.

Fourth, the solution to the problem

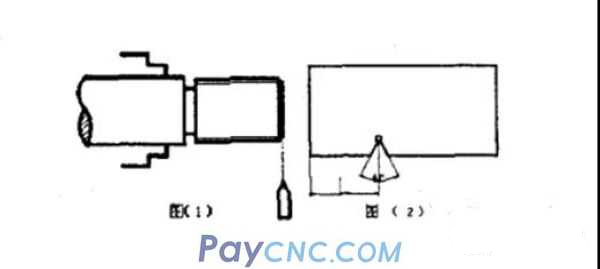

If the tool is damaged during threading or you want to change a fine turning tool to finish the thread. Then after the new knife is installed, just re-adjust the knife. Add WeChat: Yuki7557 sends a copy of the macro program tutorial. When setting the tool, the x direction is easier to align. The key is the z direction. Many people move the tip of the tool to the end face of the workpiece to feel the tool, as shown in figure (1). The tool setting error ratio

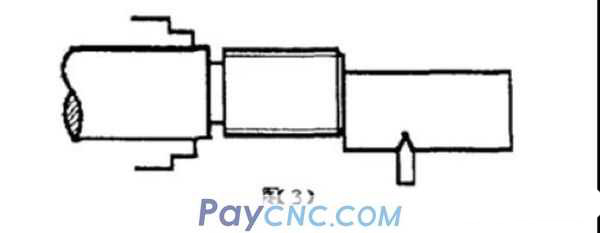

Larger, rough cars are OK. Refined cars will not work. Here, I will introduce a method to you. You can use the existing angle template or a template made by yourself, as shown in Figure (2). Accurately measure the distance of L in the figure.

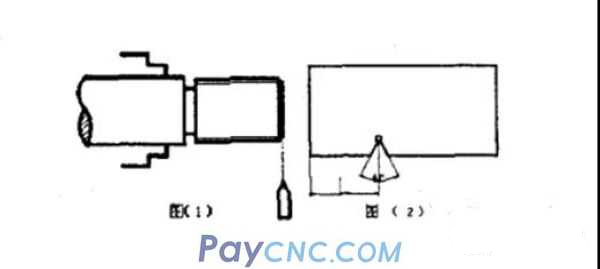

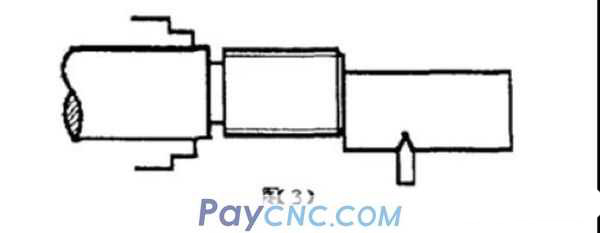

When setting the tool, as shown in (3). The model leans against the end face of the workpiece. Move the knife to the inner corner of the model. Then input the Z force to the tool compensation value L into the system. This tool setting method has high precision and is suitable for precision tool setting.

2) Repair of single or small batch of threaded parts

If the threaded parts are removed after the car is finished, it is found that the depth of the teeth is not enough, and it needs to be repaired by new clamping. First of all, to solve the problem of beating after reassembly, you can make an open sleeve to eliminate the beating error. I believe most people know this method and will not talk about it again. The rest is to solve the problem that the knife cuts along the original spiral groove to prevent messy teeth. This problem is well solved on ordinary lathes. But it is more difficult on CNC cars. The method used by many people is shown in Figure (4).

After aligning the knife, let the knife not touch the parts, and run the thread at a slow speed without machining program. The distance L from the tip of the mesh to the spiral groove, and then repair the position of the thread cutting starting point in the program. Let it be offset from the original point A by a distance L to point B. Then repeat the above process, add WeChat: Yuki7557 to send a macro program tutorial, modify the distance L. So repeatedly. Until the tip of the knife cuts into the thread groove. This method requires constant adjustment of the distance of L. Very time-consuming. In fact, we can solve these ten problems by slightly modifying the original program. Just change the thread length in the program to about 2mm. The workpiece is clamped. After the turning tool is aligned, transfer the program. Turn a knife with very short and shallow threads. Find the starting position of the thread on the end face, as shown in figure (5).

Suppose the starting position of the thread of the just-turned car is at point 2, and the starting position of the original thread is at point l. Draw a line AB on the chuck along point 2 and then release the jaws. Rotate the part from the first point to the second point against the marking line AB. If the workpiece moves axially during rotation, the thread cutter must be re-aligned in the z direction.

Clamp the workpiece and change the length of the thread in the program to the original value. Run the program to test the cutting once, look at the error, and fine-tune the starting point of thread cutting according to the error. As for the thread cut from the second point just now, because it is very short, it can be removed by chamfering. This method is much faster and more accurate than the previous one. The key step is to rotate the part from point 1 to point 2 accurately.

If there are a small number of threaded parts that need to be repaired, we can use the original program to make a thread again, find out the starting position of the thread, draw a line on the chuck to mark, and use the above method to repair.

3) Repair of large quantities of screw parts

If there are a large number of screw parts need to be repaired. It needs to be solved by a fast, simple and accurate method. I have summarized a method in practice for everyone to discuss.

When turning threads on a CNC lathe, you often encounter such problems: (1) The thread cutter is damaged halfway through the thread. (2) I want to change a high-speed precision turning tool with a thread finishing tool. (3) Remove the threaded car and measure it again, and find that the depth is not enough. When faced with these same problems, we are often helpless, because after changing the tool or re-clamping the workpiece, the thread cutter is difficult to align with the original spiral groove, the starting position is not accurate, and the teeth are always messy.

2. The principle of turning thread on CNC lathe

To solve these problems, we must first understand the principle of CNC lathe turning thread. To complete the thread cutting, the workpiece must be accurately turned one turn, and the tool feeds one lead. In order to achieve this, a spindle encoder is installed on the CNC lathe. Use its synchronous pulse as the cutting control signal of the turning point of the turning tool

The number of pulses given to the servo motor has a corresponding relationship with the spindle speed. However, there is no direct mechanical connection between the rotation of the spindle of the CNC lathe and the feed motion. Therefore, when reinstalling the tool or clamping the workpiece again, it is not so easy to make the tip of the tool cut along the original spiral groove.

3. Existing prevention measures

At present, when using CNC lathes to turn threads in enterprises, most of them use a machine tool for turning. Both coarse and fine are used—a knife and the same speed. If the knife breaks in the middle, do not remove the knife bar, and directly change the blade to prevent messy teeth. But if the rough car. The two tools of fine turning are turned separately or the parts are re-clamped, which brings about the problem of messy teeth.

Fourth, the solution to the problem

If the tool is damaged during threading or you want to change a fine turning tool to finish the thread. Then after the new knife is installed, just re-adjust the knife. Add WeChat: Yuki7557 sends a copy of the macro program tutorial. When setting the tool, the x direction is easier to align. The key is the z direction. Many people move the tip of the tool to the end face of the workpiece to feel the tool, as shown in figure (1). The tool setting error ratio

Larger, rough cars are OK. Refined cars will not work. Here, I will introduce a method to you. You can use the existing angle template or a template made by yourself, as shown in Figure (2). Accurately measure the distance of L in the figure.

When setting the tool, as shown in (3). The model leans against the end face of the workpiece. Move the knife to the inner corner of the model. Then input the Z force to the tool compensation value L into the system. This tool setting method has high precision and is suitable for precision tool setting.

2) Repair of single or small batch of threaded parts

If the threaded parts are removed after the car is finished, it is found that the depth of the teeth is not enough, and it needs to be repaired by new clamping. First of all, to solve the problem of beating after reassembly, you can make an open sleeve to eliminate the beating error. I believe most people know this method and will not talk about it again. The rest is to solve the problem that the knife cuts along the original spiral groove to prevent messy teeth. This problem is well solved on ordinary lathes. But it is more difficult on CNC cars. The method used by many people is shown in Figure (4).

After aligning the knife, let the knife not touch the parts, and run the thread at a slow speed without machining program. The distance L from the tip of the mesh to the spiral groove, and then repair the position of the thread cutting starting point in the program. Let it be offset from the original point A by a distance L to point B. Then repeat the above process, add WeChat: Yuki7557 to send a macro program tutorial, modify the distance L. So repeatedly. Until the tip of the knife cuts into the thread groove. This method requires constant adjustment of the distance of L. Very time-consuming. In fact, we can solve these ten problems by slightly modifying the original program. Just change the thread length in the program to about 2mm. The workpiece is clamped. After the turning tool is aligned, transfer the program. Turn a knife with very short and shallow threads. Find the starting position of the thread on the end face, as shown in figure (5).

Suppose the starting position of the thread of the just-turned car is at point 2, and the starting position of the original thread is at point l. Draw a line AB on the chuck along point 2 and then release the jaws. Rotate the part from the first point to the second point against the marking line AB. If the workpiece moves axially during rotation, the thread cutter must be re-aligned in the z direction.

Clamp the workpiece and change the length of the thread in the program to the original value. Run the program to test the cutting once, look at the error, and fine-tune the starting point of thread cutting according to the error. As for the thread cut from the second point just now, because it is very short, it can be removed by chamfering. This method is much faster and more accurate than the previous one. The key step is to rotate the part from point 1 to point 2 accurately.

If there are a small number of threaded parts that need to be repaired, we can use the original program to make a thread again, find out the starting position of the thread, draw a line on the chuck to mark, and use the above method to repair.

3) Repair of large quantities of screw parts

If there are a large number of screw parts need to be repaired. It needs to be solved by a fast, simple and accurate method. I have summarized a method in practice for everyone to discuss.

USD

USD