How to set internal or external hydraulic chuck on GSK988T

When we use hydraulically-clamped CNC lathes to process parts, external clamping or internal clamping clamping is required due to different workpiece processing techniques. However, when the machine tool is produced, it is generally installed and debugged according to the external clamping. When the user uses the internal clamp, in addition to the need to replace the jaws, the corresponding system parameters must be modified.

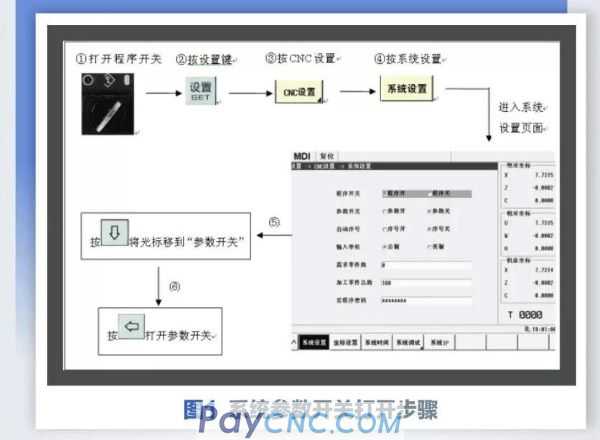

The following introduces the switching method of the working mode of the internal and external chuck of the hydraulic chuck of the GSK988T series CNC machine tool.01 Press the system [Set] to enter the parameter switch interface and turn on the parameter switch, as shown in Figure 1.

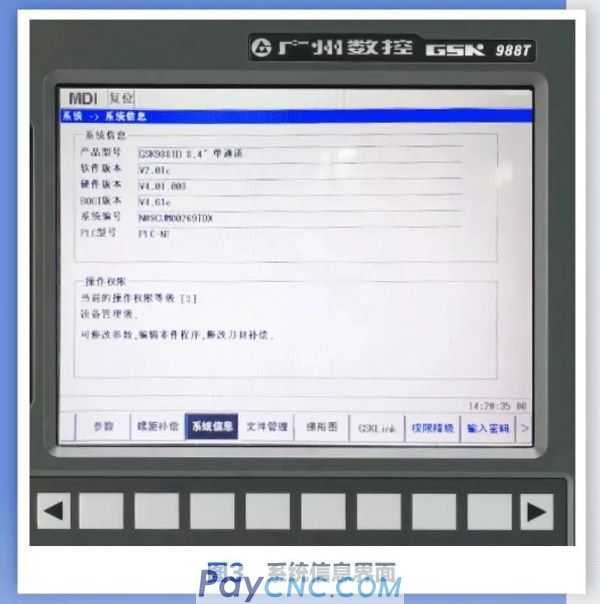

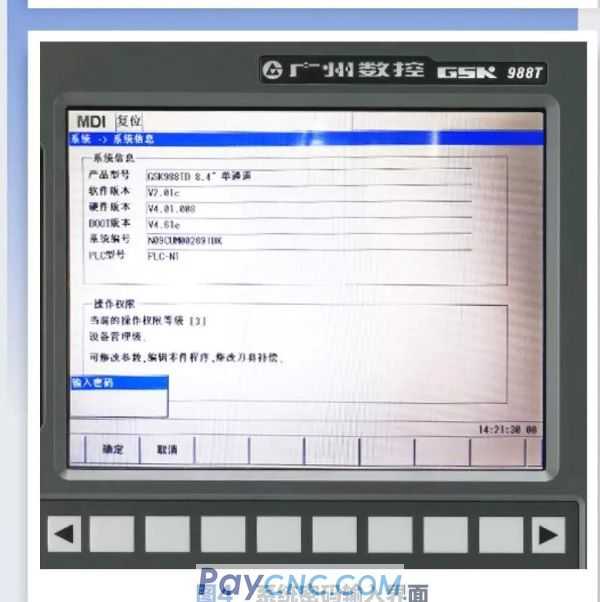

Press the [System] key on the panel, then press "System Information" at the bottom of the system screen (as shown in Figure 3), press "Enter Password" at the bottom right of the system screen to enter the password interface, and enter the level 3 (device management) password "3333333 ",As shown in Figure 4.

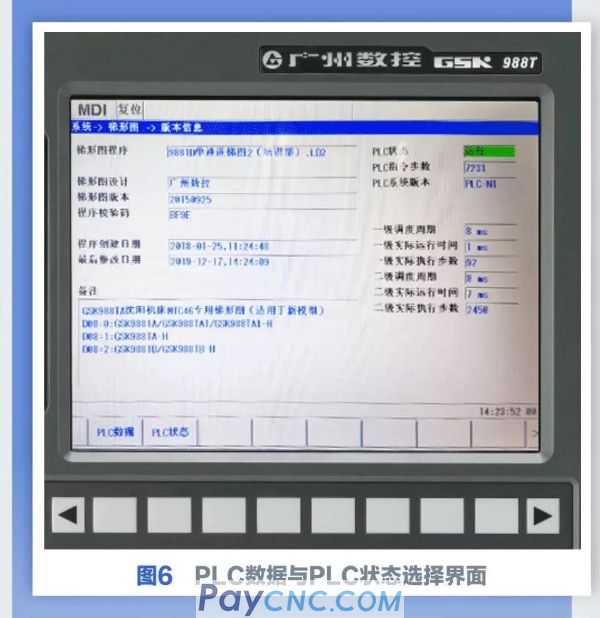

Press the system [System] key, press the "ladder" softkey below the system screen, and then press the "arrow" softkey at the bottom right of the system screen (see Figure 5).

Press the "PLC data" key (as shown in Figure 6) below the system screen to enter the K parameter setting surface in the system PLC, move the cursor to K14.2 (as shown in Figure 7), and in the entry mode, press the number Press key [0], [1] or [Enter] to modify the K14.2 parameter value, and press the "Save" key after the modification.

02 After the user changes the inner and outer jaws of the machine tool chuck according to actual needs, the system parameter K14.2 can be modified to the corresponding state.

When the value of parameter K14.2 is "0", the machine tool is in the external card mode: when the value of parameter K14.2 is "1", the machine tool is in the internal card mode

USD

USD