How to use G76 G85 G86 G87 for boring

When CNC milling is used to process fine and rough boring, it is necessary to distinguish which process parts are suitable for G76, G85, G86, and G87 instruction programming, which is easy to improve work efficiency. Today I will introduce the usage and processing purposes of these instructions in detail.

1) Rough boring cycle command G86

Instruction format:

G86 X_ Y_ Z_ R_F_;

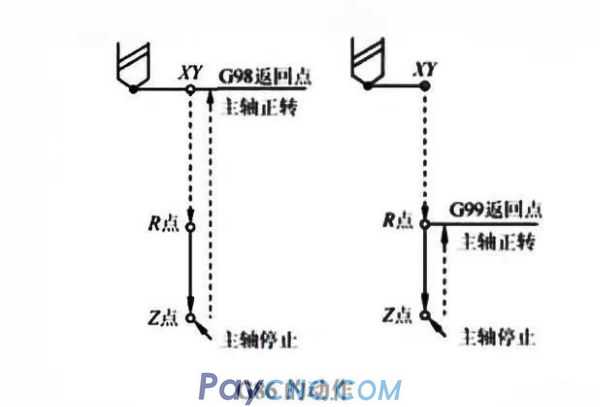

Compared with G81, the same point: command format; different point: G86's action route is that after feeding to the bottom of the hole, the spindle stops, and after returning to point R (G99) or initial plane (G98), the spindle restarts.

Application: boring of holes that do not require high precision or surface roughness.

2) Semi-precision boring, reaming, reaming fixed cycle command G85

Instruction format:

G85X_Y_Z_R_F_;

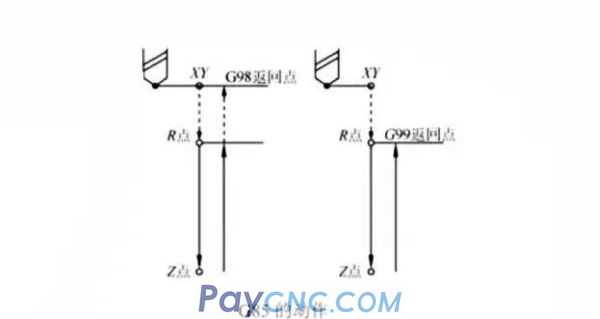

Compared with G81, the same point: the command format; the different point: The movement path of G85 is in the return stroke, from the bottom of the hole to the point R is not a rapid retraction, but the retraction at the cutting speed, so the machining accuracy is higher than G86. Learn UG programming can add a small editor QQ: 770573829 to receive learning materials and courses.

Application: more precise boring, reaming and reaming.

3) Fine boring cycle command G76

Instruction format:

G76 X_ Y_ Z_ R_Q_P_F_;

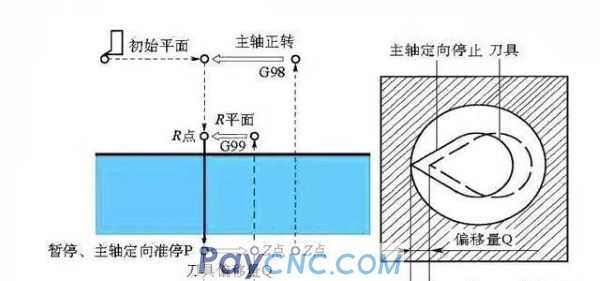

P-pause time at the bottom of the hole; Q-tool offset

Instructions:

① After the X and Y axes are positioned, the tool moves from the initial point to the R point, and starts fine boring to the bottom of the hole, then feeds out, the spindle at the bottom of the hole quasi-stops, and the tool tip leaves the processed surface Q (makes the tool) Then quickly retract the tool and reset the tool (the center of the tool returns, and the spindle resumes rotation)

②When machining, in order to prevent the tool from scratching the hole surface during the tool withdrawal, G76 fine boring command can be used.

4) Back boring fixed cycle G87

Instruction format:

G87 X_ Y_ Z_R_Q_P_F_;

Instructions:

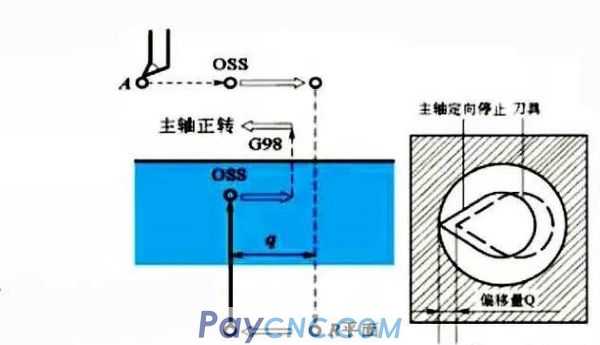

① After positioning the x-axis and the Y-axis, the orientation of the spindle is stopped → move 0 in the opposite direction of the tool tip (so that the tool tip and the hole wall have a safe distance) and quickly move to the specified R plane → move Q in the direction of the tool tip → the spindle rotates forward Start cutting, machining up to the specified Z point along the Z axis at the feed rate → the spindle is oriented again to stop, and move the Q value in the opposite direction of the original tool tip again → After quickly moving to the initial point (only G98), the tool tip returns- An original displacement Q, the spindle rotates forward.

② When using G87 mode, the tool can only be returned to the initial plane and not to the R point plane, because the R point plane is lower than the Z plane at this time.

Hole machining fixed cycle function

How to use the number of repetitions in a fixed cycle

In the fixed cycle instruction, specify the number of repetitions with the K address. In the G91 mode, if there are several identical holes with the same hole spacing, it is convenient to use the repetition times for programming.

When programming with repetitions, the 691 and G99 methods should be used.

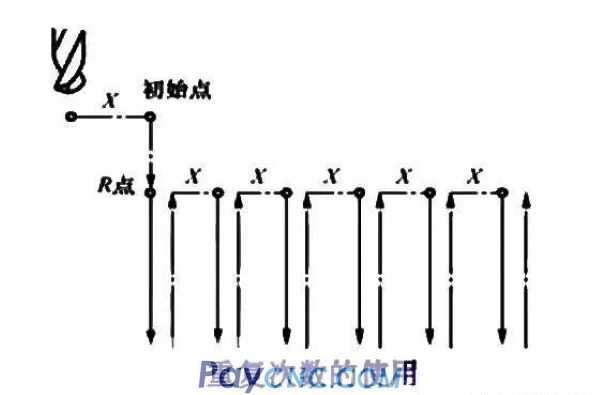

For example, when executing the block "G91 G99 G81 X50 Z-25 R-10 K6 F100", the movement path is as shown in the figure.

If it is in the absolute value mode, you can't drill 6 holes, just reciprocate 6 times at the first hole, the result is still a hole.

Cancel fixed cycle command G80

Instruction format: G80;

Instructions:

① Cancel all canned cycles and perform normal operation, R, Z and related drilling data are canceled and cleared.

②Canned cycle can also be cancelled by using G00, G01, G02, G03, the effect is the same as G80.

USD

USD