Making mold for face mask with GSK 25iMb CNC

Meltblown cloth is the core material of the mask. Meltblown cloth mainly uses polypropylene as the main raw material.

The key component of the melt-blown fabric is the melt-blown die head (spinneret), which is a precision product. On a high-hardness stainless steel, the CNC machine tool is used to drill a diameter of only 2-3 hairs. Microporous. The hole diameter is small, the hole depth is long, and the length-to-diameter ratio of the tool reaches 20: 1 during processing. The difficulty can be imagined.In order to meet the processing requirements, we choose the supporting GSK system high-speed vertical plus, combined with GSK linear motor drive. It can maximize the machining performance of the machine tool and realize the efficient and high-quality machining of micro holes.

Features

The GSK25iMb CNC system supporting the machine tool is a high-performance, high-reliability CNC system that is iteratively upgraded on the basis of the original GSK25iM series products. The system adds and optimizes related functions and performance for high-speed machining centers.

The system has G05 high-speed, high-precision smoothing and smoothing functions, and supports high-precision and efficient processing of mold parts;

The system has flexible acceleration and deceleration, which can reduce the impact during high-speed operation and extend the mechanical life;

480M large capacity program memory, convenient to store a large number of processing programs;

Match the 23-bit encoder high-speed and high-precision feed shaft motor, bringing high precision and high finish to the product;

The new generation of high-performance servo drives are equipped with parameter self-tuning, wave trap, and friction compensation functions, which can suppress vibration and eliminate quadrant traces. The tuning is simple, which can ensure high contour accuracy and high surface quality of the processed workpiece;

Support access to the smart factory network to achieve networked and information management.

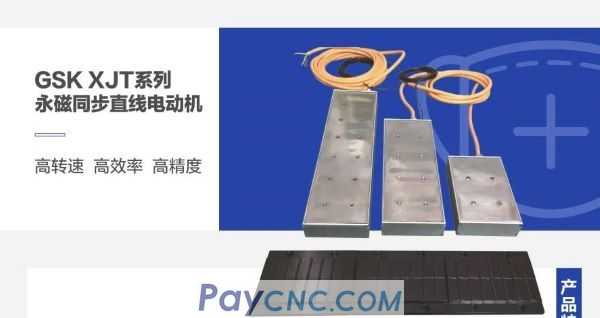

Low mechanical friction and high energy conversion efficiency

Positioning accuracy and transmission accuracy are greatly improved

Can effectively eliminate the forward and reverse gaps, small elastic deformation and high rigidity

The system has small motion inertia

High thrust density and strong overload capacity

Direct drive, simple structure and reliable operation

Fully closed loop for high-precision operation

Modular design, unlimited travel

Adopt water cooling structure with high thrust-to-weight ratio

High acceleration, high-speed operation

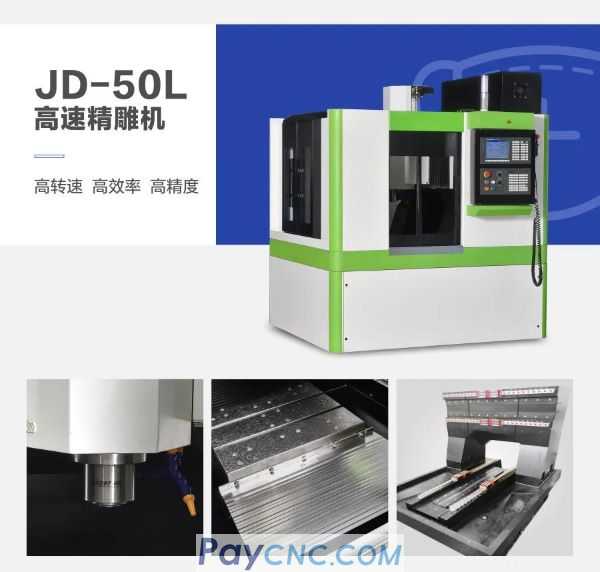

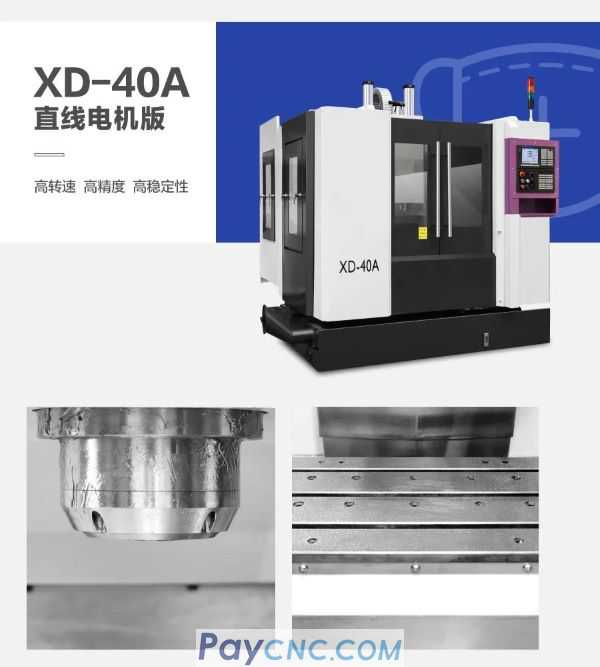

Supporting GSK25iMb CNC system, all three axes are driven by GSK linear motor;

Fast dynamic response, can realize the processing of high-gloss parts, high-speed milling, no backlash, and solve the image limit mark;

High precision and fast efficiency, equipped with HEIDENHAIN grating ruler to form a fully closed loop;

The machine bed is made of mineral casting materials and has a small gantry structure.

The whole machine tool adopts resin sand casting, and through multiple stress relief procedures, the machine tool has good rigidity;

The three-axis adopts GSK large thrust linear motor with grating ruler to implement full closed-loop control, and THK linear guide rail to achieve rapid displacement and high positioning accuracy;

Adopt built-in asynchronous electric spindle, with characteristics of light weight, small inertia, small vibration, low noise, etc., realize high speed, high precision and high running stability;

Comparing the processing efficiency with Jiangsu Xinduan TC35 CNC machine tool, take the terminal block in the feed motor as an example: CNC machine tool 23.3 seconds / piece, linear motor machine tool 14.7 seconds / piece, efficiency increased by 36%.

USD

USD