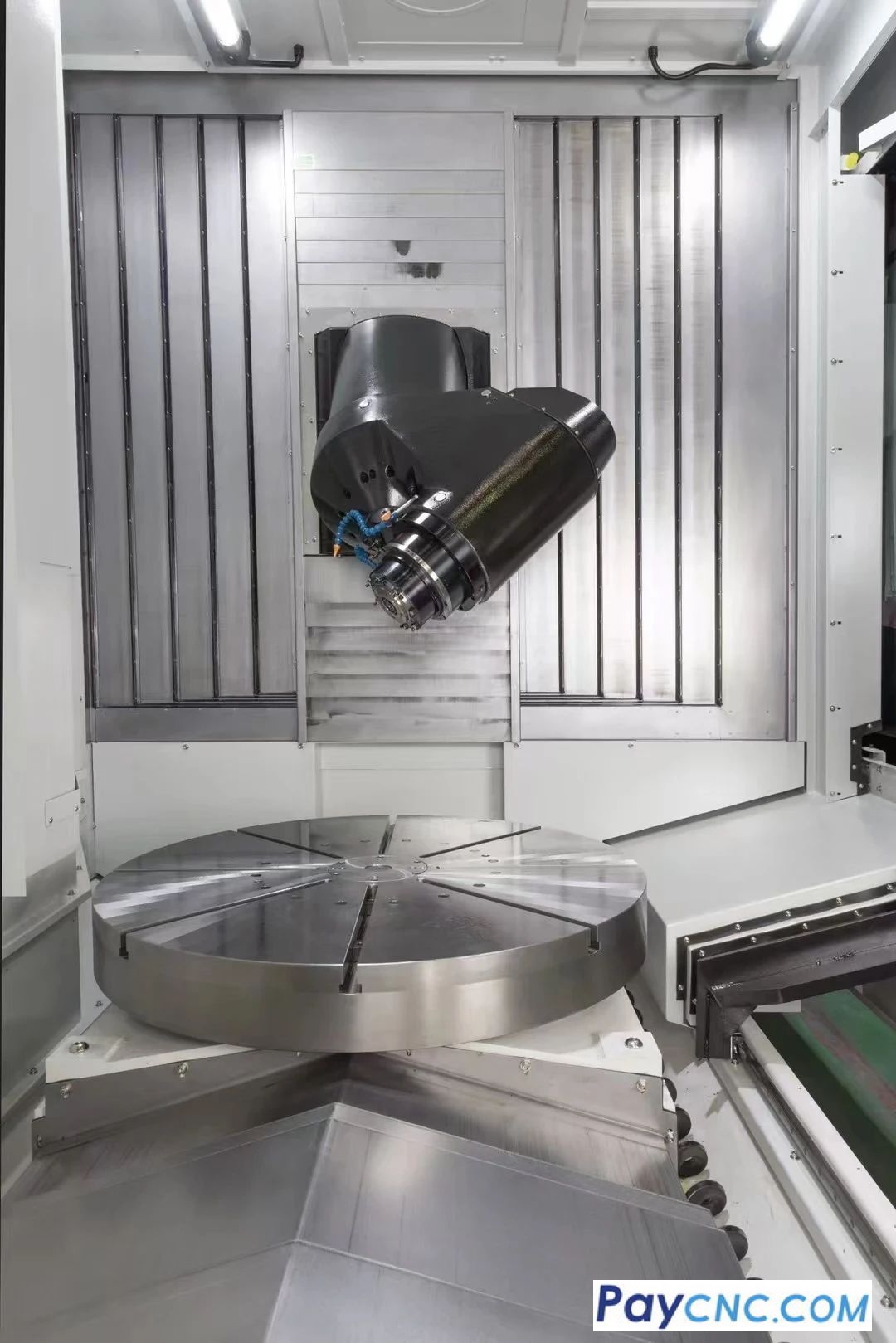

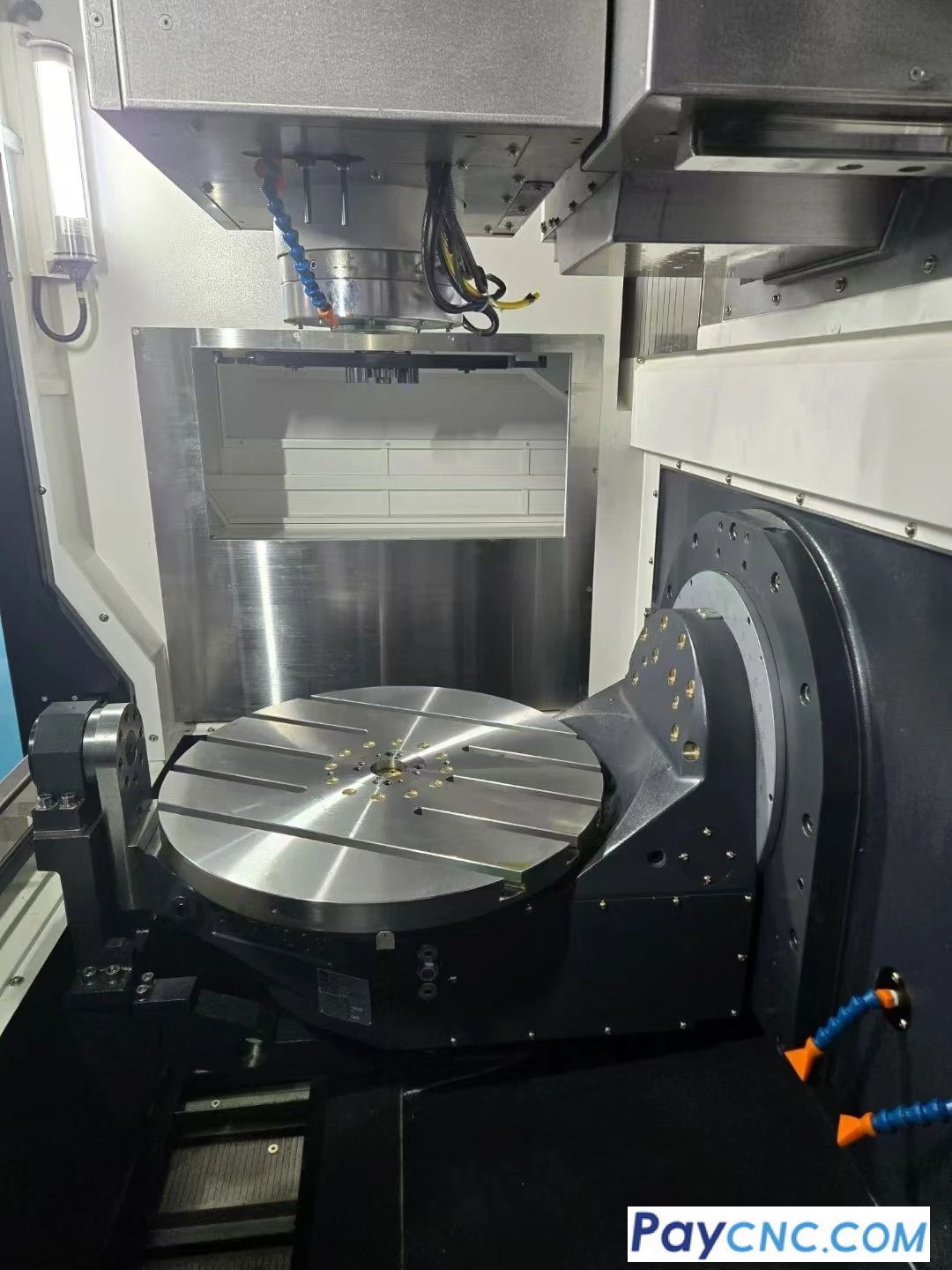

In the field of five-axis cnc machining, the two mainstream structural types —

spindle-tilting and table-tilting (cradle-type)

— significantly impact machine performance and machining outcomes. How should you choose based on your specific needs? This article offers a detailed analysis of the core differences between the two structures.

Core Differences: A Comparison Across Five Dimensions

-

Spindle Rigidity

-

Spindle-Tilting Type: Rigidity significantly decreases during tilting motion, which affects stability during heavy cutting.

-

Table-Tilting Type: Spindle remains fixed, so rigidity is unaffected by movement, offering better stability.

-

-

Machining Efficiency

-

Spindle-Tilting Type: For the same tool tip displacement, the spindle must swing through a larger angle (lever principle), resulting in relatively lower efficiency.

-

Table-Tilting Type: Movement is more direct, resulting in higher efficiency.

-

-

Impact of Tool Length on Accuracy

-

Spindle-Tilting Type: Tool length = arm length! Error = arm length × tilt angle. The longer the tool, the greater the magnified error.

-

Table-Tilting Type: Tool length is independent of swing mechanics, so it does not affect swing error, making it more forgiving for long tools.

-

-

Types of Machining Error

-

Spindle-Tilting Type: Causes both positional errors and form errors, as spindle tilting shifts the feed direction away from the tool center, possibly producing wedge-shaped holes.

-

Table-Tilting Type: Only produces positional errors from table movement; the spindle feed direction always aligns with the tool center — no additional form errors.

-

-

Effective Machining Range

-

Spindle-Tilting Type: Tilting “consumes” travel distance, so the five-axis machining maximum part diameter is smaller than its three-axis capacity.

-

Table-Tilting Type: Tilting the table does not affect horizontal dimensions, so the five-axis range is generally the same as three-axis (interference permitting). Typically, the cradle type offers a larger machining envelope for the same travel range.

-

???? Summary: Advantages and Limitations

|

Feature |

Table-Tilting Type (Cradle) |

Spindle-Tilting Type |

|---|---|---|

|

Spindle Rigidity |

✅ Excellent (fixed spindle) |

⚠️ Reduced during tilting |

|

Machining Efficiency |

✅ Higher |

⚠️ Relatively lower |

|

Long Tool Accuracy |

✅ Unaffected by tool length |

❌ Error magnifies with tool length |

|

Machining Error |

✅ Only positional error |

❌ Positional + form error (e.g., wedges) |

|

5-Axis Machining Range |

✅ Usually larger (same travel) |

⚠️ Reduced range due to tilt consumption |

|

Heavy Workpiece Suitability |

⚠️ High fixture demands; very heavy parts may not rotate |

✅ Better for very large/heavy parts |

???? Key Insight:

The cradle-type table-tilting structure generally provides superior rigidity, efficiency, precision stability, avoidance of form errors, and effective working range. It is the ideal choice for precision and high-efficiency machining.

The spindle-tilting type is irreplaceable when machining extra-large or ultra-heavy workpieces, as it avoids the need to rotate the heavy worktable or part.

???? Selection Recommendations

-

For high precision, high efficiency, and complex surface machining:

Prioritize table-tilting (cradle-type) machines — especially suitable for mold making, aerospace precision components, and medical devices.

-

For oversized or heavy-duty parts (e.g., large castings, energy equipment):

Spindle-tilting machines are often the more practical choice, though you’ll need to accept compromises in efficiency, accuracy (especially with long tools), and usable range.

-

Always request an interference diagram:

Regardless of structure type, the actual usable range of five-axis machining is heavily limited by mechanical interference. Requesting a detailed five-axis machining space interference diagram from the manufacturer is essential for correct machine selection.

The structure of a five-axis machine defines its DNA.

Understanding the core differences between spindle-tilting and table-tilting designs — and evaluating your product requirements (size, weight, precision, speed) — is the key to turning high-end equipment into a tool for real performance improvement.

Technology defines your ceiling. Choice defines your starting point.

USD

USD