- Description

Production lead time: 20 days

GSK980MDc_CNC_Milling_Machine_Controller_User_Manual.pdf (Free download, Size 8MB)

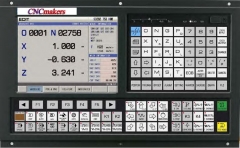

CNC system of GSK 980MDc drilling and milling machine

There are 3-kind of structures: horizontal, vertical and separation types, which are adapted with 8.4" true color LCD and supported the corresponding functions, for example: ladder diagram on-line monitoring, on-line drilling CAM function, on-line programming leading, plane drilling automatic programming, automatically locate the center etc. As well, they are supported the 1/0 unit extension The GSK980MDc series products with high cost-performance are regarded as the best partner of the common CNC milling and drilling machine tool!

Technical Features

o 5-axis control

o The least controllable precision 0.1µm, the top movement velocity 60m/min.

o Standard GS2000T -N series strong overloading servo unit, the servo motor position feedback uses 5000 ppr encoder.

o It can be carried out the spindle orientation, rigid tapping, circular interpolation and index table control.

o Build-in PLC, ladder diagram on-line display, real-time monitoring, support the 1/0 unit extension

o It owns the on-line drilling CAM function, on-line programming leading, plane drilling automatic program, and automatically locate the workpiece center, etc., convenient programming and fast operation.

o MDI multiple blocks execution

o It supports 54 workpiece coordinate systems, coordinate rotation, proportion scaling, mirror, automatic chamfering, statement macro command, and provides 12 kinds of canned cycle commands and 23 kinds of compound circular command; the programming is flexible and convenient.

o 40M program memory, 10000 component programs; support the U-disk program machining and serial communication DNC machining.

o 6-level operational authority administration, 32-times time-limited shutdown.

o 8.4 inch true color LCD and it supports multiple languages display, such as the Chinese, English and Russian.

Online CAM function

The system can be displayed the file and treated it with postposition without programming the machining program of automatic drilling, after the CAD file is led into the system. .

Plane milling point-catching machining

The machining program can be produced directly by reading the rectangle or 3 points of arc, and then the milling machining of plane is completed.

Canned circular / compound circular command

The system provides multiple canned circular and compound circular commands to simplify the programming and the machining operations,

for example the drilling/boring/tapping, linear/rectangle/arc consecutive drilling, rigid tapping, round groove/rectangle groove rough-milling and full-round/rectangle fine-milling can be carried out by these

User need not to memory the G command format and the programming leading function is gradually prompted the command information to help completing command edition and avoid the edition error or omission.

Flexible and convenient pic

To monitor the on-line ladder diagram and renew it by U disk;

it is very convenient to operate.

Technical Specification

USD

USD