Your position: Home > Milling CNC Controller

- Description

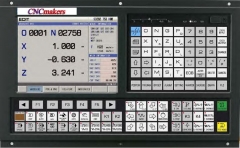

KY-3000M-V Milling CNC Controller

KY3000M-V Milling CNC Control

Functional characteristics

Number of control axes: 5 feed axes, 2 analog spindles;

Number of linkage axes: 5 axes

10.4-inch widescreen LCD with 800×600 resolution

Adopt 32-bit high-performance CPU and very large-scale programmable device FPGA

56M user storage space

Real-time all-round self-diagnosis function, real-time display of various states of the system

Feed per minute, Feed per revolution

Metric and imperial input methods

The machine tool returns to the reference point

Rapid override: F0, 25%, 50%, 100%, a total of four levels of real-time adjustment

Feedrate override: 0~150%, sixteen levels of real-time adjustment

1-way spindle encoder feedback, the number of spindle encoder lines can be set (100p/r~5000p/r)

Transmission ratio of encoder and spindle: (1~255): (1~255)

Spindle speed: can be given by S code or PLC signal, the speed range is 0r/min~9999r/min

Spindle override: 50% to 120%, a total of 8 levels of real-time adjustment

Interpolation method: linear interpolation, circular interpolation (supports three-point circular interpolation), flexible tapping

Automatic chamfering function

Spindle constant linear speed control

ISO code, support statement macro code programming, support relative coordinate, absolute coordinate and mixed coordinate programming

Program call: support macro program call with parameters, 4-level subprogram nesting

With rotation, scaling, polar coordinates, canned cycle and a variety of milling compound cycle functions

Independent backlash compensation for each axis

Pitch error compensation: the number of compensation points, compensation interval and compensation origin can be set

Tool radius compensation, tool length compensation, tool wear compensation, tool life management

Tool offset execution mode: modify coordinate mode, tool movement mode

The maximum speed, acceleration and deceleration of each axis are independently set

Emergency stop, hardware travel limit, software travel check

Chinese and English page switching

Display real-time time, number of processed pieces, processing time and other information

Various interpolation command functions and M, S, T functions, etc.

Data backup and recovery, upgrade function

KY3000M-V Milling CNC Control

Functional characteristics

Number of control axes: 5 feed axes, 2 analog spindles;

Number of linkage axes: 5 axes

10.4-inch widescreen LCD with 800×600 resolution

Adopt 32-bit high-performance CPU and very large-scale programmable device FPGA

56M user storage space

Real-time all-round self-diagnosis function, real-time display of various states of the system

Feed per minute, Feed per revolution

Metric and imperial input methods

The machine tool returns to the reference point

Rapid override: F0, 25%, 50%, 100%, a total of four levels of real-time adjustment

Feedrate override: 0~150%, sixteen levels of real-time adjustment

1-way spindle encoder feedback, the number of spindle encoder lines can be set (100p/r~5000p/r)

Transmission ratio of encoder and spindle: (1~255): (1~255)

Spindle speed: can be given by S code or PLC signal, the speed range is 0r/min~9999r/min

Spindle override: 50% to 120%, a total of 8 levels of real-time adjustment

Interpolation method: linear interpolation, circular interpolation (supports three-point circular interpolation), flexible tapping

Automatic chamfering function

Spindle constant linear speed control

ISO code, support statement macro code programming, support relative coordinate, absolute coordinate and mixed coordinate programming

Program call: support macro program call with parameters, 4-level subprogram nesting

With rotation, scaling, polar coordinates, canned cycle and a variety of milling compound cycle functions

Independent backlash compensation for each axis

Pitch error compensation: the number of compensation points, compensation interval and compensation origin can be set

Tool radius compensation, tool length compensation, tool wear compensation, tool life management

Tool offset execution mode: modify coordinate mode, tool movement mode

The maximum speed, acceleration and deceleration of each axis are independently set

Emergency stop, hardware travel limit, software travel check

Chinese and English page switching

Display real-time time, number of processed pieces, processing time and other information

Various interpolation command functions and M, S, T functions, etc.

Data backup and recovery, upgrade function

USD

USD